•

Checks during production

Disan

’s central vacuum cleaners and their

components are repeatedly subjected to quality

and functional checks by highly qualified technicians

during its manufacturing, in order to guarantee a

long operation life and perfect operation for

professional use. In this way it is guaranteed that

Disan

’s products leave the manufacturing

department in perfect conditions.

•

Checks on delivery (to be performed by

the client)

All the material shipped was carefully controlled

before its delivery to the forwarder.

This handbook is attached to the packaging in

such a way as to be clearly visible.

•

Indications on handling

Lift the pallet carefully using the lift truck fitting this

purpose.

Since the dust separators are particularly tall,

check the stability and balanced positioning of the

load on the forks. When moving, keep the load as

low as possible for more stability and visibility,

then operate with the maximum caution.

5

Central Vacuum Systems

It is the purchaser’s responsibility always to con-

trol the goods on delivery and check that they

were not damaged during their transport. If a damage

is found, accept the goods with reservation,

specifying your observations on the delivery note.

In case of damage of the material, inform

immediately the carrier for subsequent damage

compensation.

•

Check of the finished system

The installer checks the system and performs

a series of functional checks during its installa-

tion.

The modulus of the motor suction are separately

furnished on the pallet. In the waste container you

will find a pipe connection for the dust and motor

separator, connection couplings and tighten

wrappers.

•

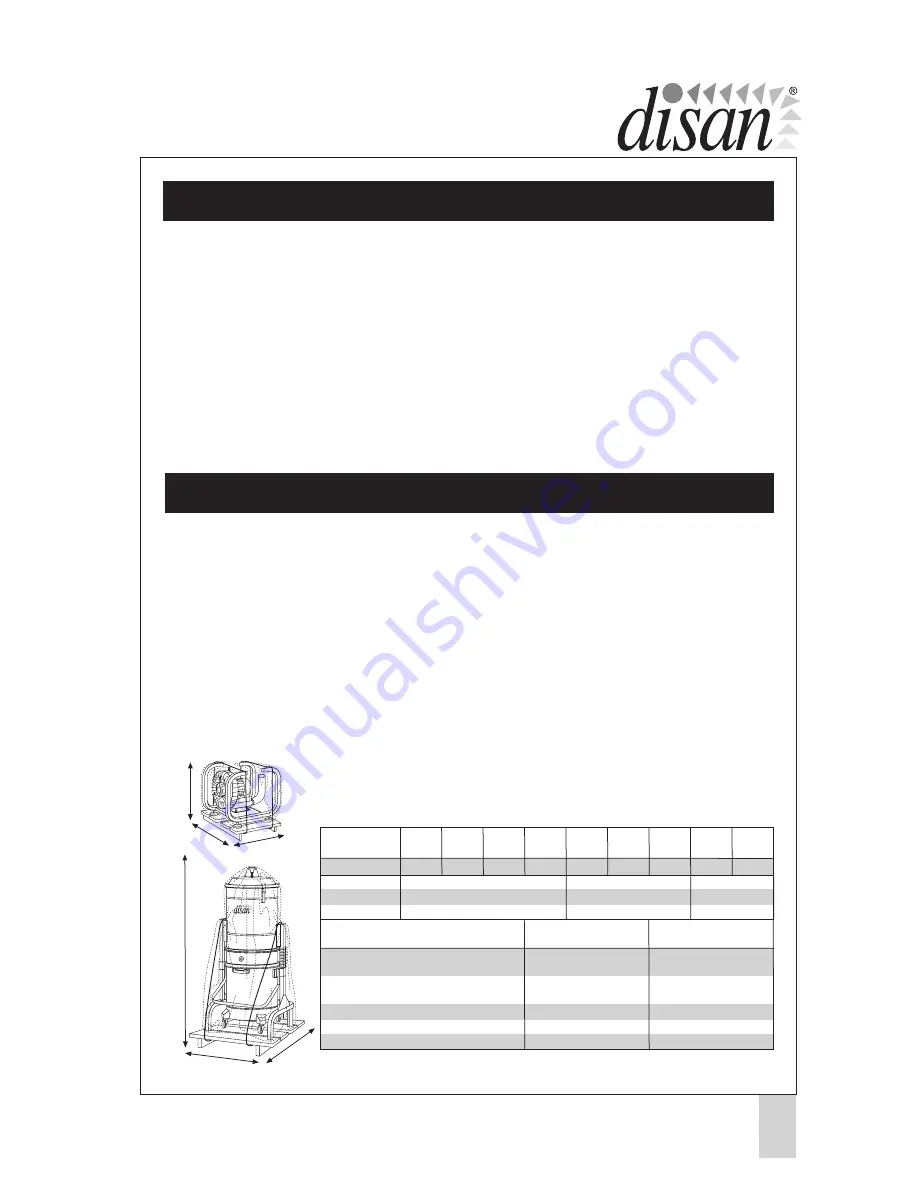

Dimensions of the central vacuum cleaner

The dust separator and the motor(s) are separately

mounted on pallets designed for this purpose and

shrink-wrapped and box packing.

The following calculation of sizes and weights

includes packaging. Measures are in centimeters.

UNLOADING AND HANDLING OF THE EQUIPMENT

Q U A L I T Y C H E C K S

H

W

D

H

W

D

Z 820

Engines

185

57

62

72

82

172

A01

B01

BC100i CD125i

B02

C03

D02

F03

H02

Weight kg

Width

Depth

Height

78

94

192

135

190

80

120

162

358

405

80

120

75

522

80

120

200

Dust separator

Separator 100l

Separator 125l

Weight without automatic

filter-shaker kg

Weight with automatic

filter-shaker kg

Width

Depth

Height

95

100

72

82

172