10(35)

User manual in Original

Dok. ref: User manual 500A-ATF-K Rev. F

DISPERATOR AB

Tel: +46 8 724 0160

E-mail: info@disperator.se

Mälarvägen 9, SE-141 71 Segeltorp, Sweden Fax: +46 8 724 6070

Web page: www.disperator.se

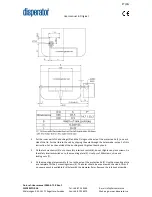

3.2.

Technical Specification

Flush pipe or flush tower

with air gap to sink

½”BSP, Male (optional)

Flushing nozzle for clamp

connection of hose,

½”

For detailed drawing

of cover guard with

safety interlock switch

see view to the right.

Side view

Back-flow preventer

(vacuum valve),

½”BSP,

Male, see (1)

Reinforced flexible

hose

½” for flushing

water, see (1)

Line strainer,

½” BSP, Female

Solenoid valve, IP65,

½”

BSP, Female, see (2)

Top view (A-A)

f

g

e

Disposer inlet

diam. 80mm

To suit drain con-

nection disposer

with outlet can

be turned and

positioned in any

direction

a

Disposer housing,

stainless steel

(EN 1.4301, AISI304

c b

Motor IP55

Air inlet in bottom plate

d

for motor cooling, min

15mm clearance

Torque protection

bar, see (1)

Disposer outlet to be

connected to a water trap,

see (1). Slope of drain

pipe 2:100 to 5:100

Cover guard

supported by a

spindle and a leg

Screw joint assembly

below sink outlet.

No welding required

Safety interlock

switch (IP67)

assembly for sink

AT-nipple

3”

BSP, Male

Gasket, 2 pcs.

(in and under sink)

Upper clamping

ring

Lower clamping

ring

Motor cable outlet

and 2 m cable, see (2)

All measurements in mm

Adjustable legs 3 pcs. for model

520, 530, 550 and 575. Optional

for model 510 and 515, see (3)

3 clamping screws

Locking ring

BS-flange 3

”

BSP, Female

900

m

in

30

m

in

300

65

75

-80

A

A

Technical specification

510A

515A

520A

530A

550A

575A

Normal capacity, kg/hr.

300

400

500

700

850

1000

Electrical power, kW

0,75

1,1

1,5

2,2

4,0

5,5

Rated current, A for:

400V / 3 ph. / 50 Hz

2,1

2,6

3,6

5,2

8,6

11,5

440V / 3 ph. / 60 Hz

2,1

2,4

3,5

5,0

7,5

10,0

480V / 3 ph. / 60 Hz

1,9

2,6

3,5

4,6

7,2

9,6

Other 3-ph voltages available 1-ph 220-240V, 50/60Hz also available for models 510 and 515.

Control voltage For marine installation the same as motor voltage. For land installation 230V/50Hz.

Fuse rating, slow

10A

10A

10A

16A

16A

16A

Gross / net weight, kg

31 / 28

32 / 29

37 / 33

50 / 47

53 / 50

59 / 56

Measurement a

151

151

151

176

176

176

Measurement b

460 see (3)

460 see(3)

583

560 see (4)

560 see (4)

655

Measurement c

See (3)

See (3)

583-763

560-740 see (4)

560-740 see (4)

655-835

Measurement d

40

40

40

75

75

75

Measurement e

2”

BSP,

Female

2 ½”

BSP,

Female

Measurement f

253

253

253

310

310

310

Measurement g (legs)

See (3)

See (3)

204

236

236

236

The Disposer works in the temperature range -5°C - +40°C

(1) Installation material needed but not incl. in standard delivery are:

• main electrical safety switch,

• flexible hose R½” for cold flush water,

• backflow preventer for flush water,

• water trap for connection to disperator outlet,

• torque protection bar for fixating the disposer.

Can be ordered from DISPERATOR.

(2) For connection to start/stop unit including contactor and overload

protector (IP66) placed on wall/bulkhead. Start/stop unit to be

connected to main electrical safety switch, see (1).

(3) 3-ph unit without legs as standard. Legs available as option and

then with same measurement b, c and g as for model 520. 1-ph unit

with legs as standard and with same measurement b, c and g as for

model 520.

(4) Short version (b = 525 mm and c = 525-705 mm) and long version

(b = 655 mm and c = 655-835 mm) available as option.

(5) User manual with installation and service instructions,

wiring diagram, laminated operating instructions and

laminated safety instructions included in delivery.