9(35)

User manual in Original

Dok. ref: User manual 500A-ATF-K Rev. F

DISPERATOR AB

Tel: +46 8 724 0160

E-mail: info@disperator.se

Mälarvägen 9, SE-141 71 Segeltorp, Sweden Fax: +46 8 724 6070

Web page: www.disperator.se

2.

Company Profile

Disperator’s business idea is to provide innovative and adaptable waste disposal equipment for

kitchens on land as well as at sea, and for the food industry. Our disposers produce finely ground food

waste which can be anaerobically digested and is also suitable for composting, which is of use to

society.

With over 60 years of experience in the field of production and development, our dedication has

resulted in the unique dependability which is needed within the marine industry. Furthermore, our

innovativeness has provided commercial kitchens on land with an alternative approach to handle food

waste separation at source, complying with modern demands and being economically reasonable.

Our assortment is unique! Disperator is the only manufacturer that offers all types of installation

possibilities in a kitchen. Our basic range consists of six different sizes of waste disposers, which may

be combined with 12 different mounting assemblies. Further, the advantage of the basic model’s

design, is that the waste disposers may easily be integrated into other manufacturer’s mounting

assembly or furnishings without difficulty. Thereby, designing each workplace in a kithen or galley to

its specific requirements regarding function, ergonomics and economy.

3.

Product Description and Technical Specification

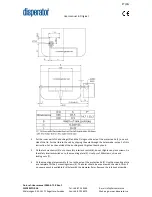

3.1.

Food Waste Disposer 500A-ATF-K EXCELLENT SERIES with Protective Lid for

Installation in Sink and Dishwashing Line

Disperator food waste disposers are used in kitchens and galleys around the world, providing an

efficient and immediate removal of food waste whenever the need arises and thereby improving

hygiene in the working environment, eliminating bad odors and bacteria formation and minimizing

manual handling.

Our product range is designed with the user’s needs in focus and meets today’s requirements for

handling of food waste. The high quality grinder of specially alloyed steel together with the unique and

well-proven sealing design between the grinder and motor provides the user with many years of

operational reliability and low maintenance cost. The disposer’s life span is extended further by the

outer housing of stainless steel EN 1.4301 (AISI 304) and protection class IP55 for electrical

components as standard.

The wide range of disposer sizes makes it easy to adjust any installation to fit any workplace in a galley

or kitchen. With an ATF assembly installation is simplified as no welding is required when mounting

on-site. The unit is installed in the sink’s existing drain outlet, with diameter 90mm, using a screw joint

reinforcement. The BS-flange is mounted onto the ATF assembly and the grinder is then bolted onto

the BS-flange. To prevent accidental access to the grinding chamber during operation the disposer

inlet is covered by a protective lid. If the lid is opened during operation the safety interlock switch

activates and shuts down the disposer. The lid also serves as a splash back and reduces the risk of

cutlery falling into the disposer by mistake.

Standard delivery includes a complete start/stop unit with contactor and motor overload protector, a

flushing nozzle for installation in sink wall or flush pipe/tower, and a complete solenoid valve with line

strainer. These items, as well as the protection lid with safety interlock switch, are to be installed on

site. Cold water will automatically flow when the disposer starts, flushing the food waste into the

grounding chamber, and then into the sewer system or a storage tank.

Food waste disposers within the Disperator Excellent Series have the Declaration of Compliance issued

by DNV, verifying compliance with applicable sections of MARPOL consolidated edition 2011/2012

ANNEX V for disposal of ground food waste into the open sea.