User manual in Original

Doc. ref: 500A_GTS-E65_am_en_210608

DISPERATOR AB

Tel: 08-724 0160

E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp

Web page: www.disperator.se

22 / 48

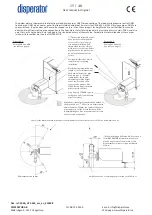

6.3. Connection of Pump Outlet to Drain Waste Pipe going to Tank

The drain waste pipe installation going to tank for the delivered machine must only be made by an

authorised installer of sewer supply

for pressurized pipes

and in accordance to valid local regulations.

6.3.1. To Check before the Connection is made

Check with the installer of the drain waste pipe going to tank to confirm that:

•

hose, tubing, fittings and any valves used have the pressure class PN16

,

•

pipe draw to tank outside building has been done in the ground on a frost-free depth, or

otherwise protected against freezing,

•

monitoring of the tank level exists, which also stops the machine when the tank is full,

•

the tank is ventilated,

•

frost-free flushing water outlet with hose and gun are available when emptying the tank.

6.3.2. Specification and Connection of Drain Waste Pipe

Use a movable flange with gasket on the drain line when this is connected to the machine’s pump

outlet DN65 (outer Ø187 mm, 4x mounting holes Ø18 mm on hole circle Ø145 mm).

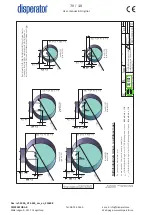

Never reduce or increase the inner diameter of the drainpipe that goes to tank. If DN65, PN16

pipe is not used, this can cause the drainage pipe to break, or alternatively there will be a stop in

the pipe. The reasons for this are that if the GTS-processor is connected to a drainpipe with:

*

less diameter than the pump outlet

, the internal resistance of the drainpipe will increase

exponentially, which can cause the pump and / or pipe to break apart.

*

larger diameter than the pump outlet

, the flow rate in the drain pipe is lowered, and the food

waste therefore settles more easily (i.e. lays more easily on the bottom of the pipe), and to a

greater extent only the liquid phase moves to the tank. Over time, this can lead to blockage in

the pipe.

The only reason to increase the inner diameter of the drainpipe is if several GTS-processors are

connected to the same main line that goes to one and the same tank.

Consult us at Disperator - we will be happy to assist you with the necessary calculations to obtain

a reliable facility.

Summary of Contents for 500A-GTS-E65 EXCELLENT SERIES

Page 2: ......