User manual in Original

Doc. ref: 500A_MB_am_en_210602

DISPERATOR AB

Tel: 08-724 0160

E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp

Web page: www.disperator.se

19 / 41

18 / 41

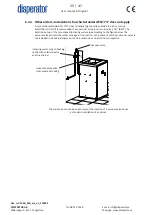

6.2. Connection of flushing water

For the machines ordered for connection to flushing water according to the requirements of standard

EN 1717 (in the UK also WRAS), or to be installed in countries where this standard must be complied

with, the machine’s draft flushing water is delivered according to these requirements to prevent con-

tamination by suction in drinking water pipes.

This standard EN 1717 defines five liquid categories that are or could come into contact with drinking

water. Category 5 is the category with the highest protective requirements and which applies in all

kitchens where food is handled, regardless of whether food waste management equipment is there

or not. If stated when ordering, all Disperator’s machine models can be delivered in accordance with

the requirements for category 5, ie. the category with the highest protection against contamination

of drinking water pipes.

Connection of flushing water to the delivered machine may only be carried out by a qualified VA in-

staller and in accordance with current local VA regulations. DISPERATOR takes no responsibility for,

according to standard EN 1717, a machine that is incorrectly connected to the drinking water line.

The machine’s automatic rinsing water control is to be connected to cold rinsing water (hot water is

not needed).

6.2.1. Water pipe DN15

To provide the correct amount of flushing water to the machine, the incoming water pipe (incl.

accessories and protection devices against suction, cut-off valves, etc.) must have the same

dimension as the connection to the machine assembly, ie. DN15. No throttling may exist up to

the flushing water connection on the machine.

6.2.2. Line Strainer DN15 and Solenoid Valve DN15

The delivered line strainer, DN15 must be mounted in the flow direction before the solenoid

valve, DN15 in the incoming cold water pipe to the machine. Also make sure that the line

strainer and solenoid valve are mounted in the correct flow direction (see the arrow on these

components), and that the nut on the line strainer (which is to be opened when cleaning the

line strainer) is directed downwards. Line strainer and solenoid valve have G½” (BSPP), internal

thread.

For funnel mounting that is welded into other manufacturers’ table tops / workbenches, and for

freestanding cabinet and table mounting, these components are pre-assembled from the factory

on the assembly for connection to cold water supply. Connection to these assemblies is R½”

(BSPT), external thread.

6.2.3. Hose with Protective Steel-Covered Stocking for Flushing Water, minimum

inner-Ø 9 mm

Between the incoming water pipe mounted on the wall/bulkhead, and the connection for

flushing water on the machine assembly, a hose with protective steel-covered stocking (with

minimum inner-Ø 9 mm) must be fitted. This hose absorbs the compressive push in the pipe

when the flushing water is turned on and absorbs any small vibrations which may occur during

the grinding process of the disposer. This hose is not included in standard delivery but is available

as an option from Disperator.

Summary of Contents for EXCELLENT 500A-MB Series

Page 2: ......