User Manual in Original

Dok. ref: 550A_GKF_am_sv_210525

DISPERATOR AB

Tel: 08-724 0160

E-mail: info@disperator.se

Mälarvägen 9, 141 71 Segeltorp

Web page: www.disperator.se

14 / 35

6.3. Start Up and Final Testing

6.3.1. Check before Start Up

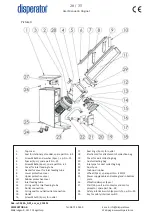

Loosen the knob and lift off the inlet feeding tube from the front panel of the machine.

Check that the rotary shredder in the inlet opening of the machine turns freely in both directions

by hand, and make sure that no foreign object has been dropped into the grinding unit during

installation.

Refit the inlet feeding tube.

6.3.2. Checks during Start-up

6.3.3. Final Measures

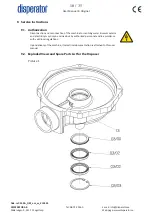

1. Attach a collection bag to the glass crusher outlet using the pre-mounted elastic cord (see

photo in section 5.2. above). Make sure the bag closes tightly against the O-rings on the

outlet.

2. Start the glass crusher to determine that the rotary shredder is spinning.

3. While the glass crusher is running, check its automatic function for collecting glass dust by

placing a thin flat paper over the entire opening of the inlet feeding tube. The paper should

then remain on the tube by the created under-pressure in the crusher. If the paper drops

from the tube, it leaks somewhere along the O-ring between the inlet feeding tube and the

crushing unit. Then check:

a) that this O-ring is correctly mounted on the tube,

b) that this O-ring is undamaged,

c) that this O-ring´s sealing function is not disturbed by foreign objects.

4. Make sure that the safety interlock switch works properly according to section 6.2.8 above.

If the machine fails to operate, see section 8.3. ”Trouble shooting” in this manual.

Before the documentation and the jam release wrench for the crushing

unit are handed over to the personnel responsible for the machine, instruct

this personnel about the operation and daily maintenance of the machine,

especially about what is said under section 7 and 8 of this manual.

6.2.8. Check of the function of the Safety Interlock Switch

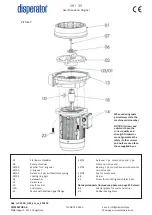

The inlet feeding tube is fixed with a knob against the front panel of the glass crusher.

a) Check the function of the safety interlock switch (the key switch) by loosening the knob so

that the inlet feeding tube is released. The electrical connection must be broken when there

are a number of threads turns left on the knob, i.e. before the inlet feeding tube is released.

Check that the machine idle run stops before the inlet feeding tube can be released and

removed.

b) If necessary, fine-tune the positioning of this switch and make sure it is properly fixed.

c) Ensure that the key mounted on the inlet feeding tube can easily move in and out of this

switch.

d) Also make sure that the important O-ring on the inlet feeding tube, that will seal against the

crushing unit and protect the switch from crushed glass, is in place and in good condition.

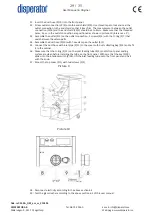

Fasten the laminated operating and safety instructions (included in delivery)

in a place on the wall / bulkhead where they are easily seen by the operator

before the start of the machine.

Summary of Contents for EXCELLENT 550A-GKF Series

Page 2: ......