11

DITEC S.P.A - IP1580 30/06/99 - CS61/CS61E

DECLARATION BY THE MANUFACTURER

(Directive 98/37/EC, Annex II, sub B)

Manufacturer:

DITEC S.p.A.

Address:

via Mons. Banfi, 3 - 21042 Caronno Pertusella (VA) - ITALY

Herewith declares that the electromechanical automatic system series CS61E-CS61

- is intended to be incorpored into machinery or to be assembled with other machinery to constitute machinery convered by Directive

98/37/EC, as amended;

- is in conformity with the provisions of the following other EEC directives:

Electromagnetic Compatibility Directive 89/336/EEC, as amended;

Low Voltage Directive 73/23/EEC, as amended;

and furthermore declares that it is not allowed to put the machinery into service until the machinery into which it is to be incorporated or

of which it is to be a component has been found and declared to be in conformity with the provisions of Directive 98/37/EC and with

national implementing legislation.

Caronno Pertusella, 03/06/1999.

Fermo Bressanini

(Chairman)

ENGLISH

GENERAL SAFETY PRECAUTIONS

This installation manual is intended for professionally competent personnel only.

The installation, the electrical connections and the settings must be completed in conformity with good workmanship and

with the laws in force.

Read the instructions carefully before beginning to install the product. Incorrect installation may be a source of danger.

Packaging materials (plastics, polystyrene, etc) must not be allowed to litter the environment and must be kept out of the reach of children

for whom they may be a source of danger.

Before beginning the installation check that the product is in perfect condition.

Do not install the product in explosive areas and atmospheres: the presence of flammable gas or fumes represents a serious threat to

safety.

Before installing the motorisation device, make all the structural modifications necessary in order to create safety clerance and to guard

or isolate all the compression, shearing, trapping and general danger areas.

Check that the existing structure has the necessary strength and stability.

The manufacturer of the motorisation device is not responsible for the non-observance of workmanship in the costruction of the frames to

be motorised , nor for deformations that may be occur during use.

The safety devices (photoelectric cells, mechanical obstruction sensor, emergency stop, etc) must be installed taking into account: the

provisions and the directives in force, good workmanship criteria, the installation area, the funtional logic of the system and the forces

developed by the motorised door or gate.

The safety devices must protect against compression, shearing, trapping and general danger areas of the motorized door or gate.

Display the signs required by law to identify danger areas.

Each installation must bear a visible indication of the data identifying the motorised door or gate.

Before connecting to the mains check that the rating is correct for the destination power requirements.

A multipolar isolation switch with minimum contact gaps of 3 mm must be included in the mains supply.

Check that upstream of the electrical installation there is an adequate differential switch and a suitable circuit breaker.

Ensure that the motorised door or gate has an earth terminal in accordance with the safety regulations in force.

The manufacturer of the motorising device declines all responsability in cases where components which are incompatible with the safe

and correct operation of the product only original spare parts must be used.

For repairs or replacements of products only original spare parts must be used.

The fitter must supply all information corcerning the automatic, the manual and emergency operation of the motorised door or gate, and

must provide the user the device with the operating instructions.

MACHINERY DIRECTIVE

Pursuant to Machinery Directive (98/37/EC) the installer who motorises a door or gate has the same obligations as the manufacturer of

machinery and as such must:

- prepare the technical file which must contain the documents indicated in Annex V of the Machinery Directive; (The technical file must

be kept and placed at the disposal of competent national authorities for at least ten years from the date of manufacture of the

motorised door);

- draft the EC declaration of conformity in accordance with Annex II-A of the Machinery Directive;

- affix the CE marking on the power operated door in accordance with point 1.7.3 of Annex I of the Machinery Directive.

For more information consult the “Technical Manual Guidelines” available on Internet at the following address: http://www.seisnet.it/ditec/

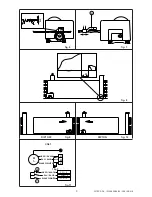

APPLICATIONS

Maximum permissible weight: 600 kg

Recommended weight: 400

Service life: 3 (minimum 10÷5 years of working life with 30÷60 cycles a day)

Applications: FREQUENT (For vehicle or pedestrian accesses to town houses or small condominiums with frequent use).

Minimum number of consecutive cycles: 15

•

Performance characteristics are to be understood as referring to the recommended weight (approx. 2/3 of maximum permissible

weight). A reduction in performance is to be expected when the access is made to operate at the maximum permissible weight.

•

Service class, running times, and the number of consecutive cycles are to be taken as merely indicative having been statistically

determined under average operating conditions, and are therefore not necessarily applicable to specific conditions of use. During

given time spans product performance characteristics will be such as not to require any special maintenance.

•

The actual performance characteristics of each automatic access may be affected by independent variables such as friction, balancing

and environmental factors, all of which may substantially alter the performance characteristics of the automatic access or curtail its

working life or parts thereof (including the automatic devices themselves). When setting up, specific local conditions must be duly

borne in mind and the installation adapted accordingly for ensuring maximum durability and trouble-free operation.