12

DITEC S.P.A - IP1580 30/06/99 - CS61/CS61E

1. TECHNICAL DATA

Power supply

230 V~ 50 Hz

Absorption

2 A

Motor power

250 W

Torque

700 N

Max. run

13 m

Max. door weight

600 kg

Speed

0.18 m/s

Intermittence

S2 = 15 min. / S3 = 25%

Temperature

-15 °C / +50 °C

Degree of protection

IP54

Weight

12.7 kg

2. REFERENCE TO ILLUSTRATIONS

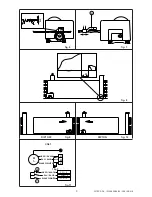

2.1 Standard installation references (fig. 1)

ATTENTION: Only use DITEC’s safety devices and accessories for installation.

1

Radio

2

Flashing light

3

Key selector

4

Connect power supply to an omni-pole switch with a contact opening gap of no less that 3 mm (not supplied

by us)

2.2 Geared motor references (fig. 2)

9 Geared motor

10 Carter

11 Release access door

12 Release

3. INSTALLATION

3.1 Preliminary checks

Check for gate stability and that the slide wheels are in good condition and the top guides do not cause any

friction. The slideway must be securely anchored to the ground and fully exposed along its full length. It must be

perfectly smooth so as to avoid jamming of the gate.

Provide an opening and closing stop.

Make sure that the gate is securely inserted in the slideway so that it cannot come out of the

slideway and fall.

Geared motor installation

Unless otherwise specified, all measurements are expressed in millimetres.

3.2 (Fig. 4) Lay a concrete foundation with buried anchoring brackets and the base plate, making sure that it is

pefectly level and smooth. Allow for 80 mm between the plate axis and the rack B . Route the cable ducts

through the two holes in the middle of the plate.

3.3 (Fig. 5) Open the release access door 11 , loosen the screw that locks the carter and lift it. Insert the

ancoring feet G at the gear motor base. Position the geared motor on to the base plate. Adjusting

gearmotor: horizontally by sliding in the ancoring feet notches, vertically with the 4 levelling screws D :

while adjusting vertically, keep the motor slightly raised above the base plate so as to allow enough

space to secure the rack and to make any subsequent adjustments, if necessary.

3.4 (Fig. 6) Secure the rack by disengaging the geared motor and opening the gate. Place the rack on pinion

15 and move the gate manually to secure the rack along its full length. Once the rack has been secured,

vertically adjust the geared motor so as to have a gap of 2 to 3 mm between the pinion and the rack. Finally,

firmly secure the geared motor by fitting shims E

and washers F .

3.5 (Fig. 7, 8) Adjusting limit switch: secure the limit stop skids H on to the rack so that the gate stops about

20 mm before reaching the stop.

ENGLISH

5

Geared motor + Electrical board

6

Photocells

7

Rubber hip / Sensitive hip

8 Opening and closing stop

13 Electrical board

14 Limit-switch spring

15 Pinion