6

2.2.3 Collection of damp, wet, oily or sticky dusts

2.3 Normal Operation

3.1 How the product ships

3.2 Items that ship separately

The Typhoon Central Dust Collector is an effective collector of dusts that are difficult or even impossible for other collectors, particularly dry collectors

such as cartridge and bag collectors, to collect. Damp, wet, sticky or oily dusts can clog the pores of paper and fabric media. In pulse clean or shaker

style self-cleaning dust collectors, these dusts will not release from the cartridges or bags, causing the dust collector to clog and quickly fail.

The Typhoon Central Dust Collector cleans the air by the combined action of centrifugal force and a thorough mixing of water and dust laden air.

The dust is separated from the air by means of a water curtain, created by the flow of air through a partially submerged stationary impeller (see

Figure 1). Air flowing through the impeller at a high velocity conveys water with it in a very turbulent sheet. Additional water is introduced at the

narrowest portion of the impeller through a specially designed slot in the bottom. Since there is a certain differential pressure through the impeller,

the water flows upward through the slot in an attempt to reach the water level on the clean air side. This water flow upward through the slot creates

increased interaction between the dust and water, thus, increased collection efficiency. Since the water flows upward in an attempt to reach the

water level on the clean air side of the impeller, the impeller opening can be decreased (resulting in higher differential pressure and collection

efficiency) by raising the water in the unit. This is accomplished by a unique and patented variable water level control box. The centrifugal force

exerted by the rapid changes in direction of flow causes the dust particle to penetrate the water film and become permanently trapped. (Figure 1)

The water in the reservoir is continually reused and since the water curtain is produced by the air flow, no pumps or nozzles are required. The

water level is maintained by the overflow weir in the control box as long as a small amount of fresh water is supplied through the make-up water

connection or by electrical controls that automatically add water, as needed to compensate for evaporation and water lost as the collected dust is

removed from the unit.

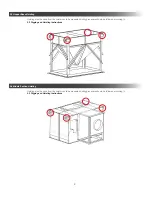

The Diversitech Typhoon Central Dust Collector is shipped with the base, cleaning, clean air, and motor-blower sections disassembled.

The people of Diversitech take pride in the quality of the products that we supply and it is our intention that our customer’s experience with our

products and services be positive and satisfying. This process begins at delivery. It is important to ensure that the product delivered is what was

ordered and that it arrives at its destination in perfect condition. Adequate preparation on the part of the buyer, together with a structured approach

to receipt and inspection, will ensure that if problems exist they are communicated swiftly and efficiently through the proper channels allowing them

to be resolved in the shortest possible time.

To reduce freight costs, Diversitech may ship items separately. The customer will be notified which equipment ships separately when the order is

placed. Items that ship separately should be set aside in an area that is clean, dry, and in a place where damage to the equipment will not occur,

see

section 6

for information on storage and protection.

SECTION 3 - PRODUCT SHIPMENT

SECTION 4 - PRODUCT RECEIPT AT THE DESIGNATED DELIVERY POINT

4.1 Responsibilities of the customer or customer’s agent

4.2 Receiving

4.3 Inspection on arrival

Ensure all loading/unloading equipment and safety equipment is on site at the time of delivery. Safe and efficient operation of the collector depends on

proper installation. Know proper laws, codes and regulations before installation starts.

Remove crates, tarps, shipping straps, etc. along with any loose items or equipment before unloading the Diversitech Typhoon Central Dust Collector.

The Diversitech Typhoon Central Dust Collector is normally shipped by truck and should be checked for damage that may have occurred in route.

Compare the collector(s) received to the description and/or drawing of the collector(s) ordered. Immediately report any differences or missing items

from the order to Diversitech. Remove loose items or components before lifting the collector from the truck.

A qualified installation and service company should complete installation of the collector and accessories.

Summary of Contents for Typhoon TY-10000

Page 26: ...26 12 4 Troubleshooting Procedure...

Page 29: ...29 NOTES...