English

-

38

Maintenance

Before After

Daily

Weekly At

least

once

each

year

Maintenance interval

in hours

25

50

100

300

Check/adjust throttle and choke cables

Check the condition of belts, belt pulleys, etc.

Change the engine oil

1)

Replace the engine oil fi lter

Clean/replace the spark plugs

Replace the fuel fi lter

Replace the air fi lter (paper fi lter)

2)

Check the caster wheels (every 200 hours)

Clean the cooling fi ns

2)

Replace the air cleaner’s pre-fi lter

2)

(foam)

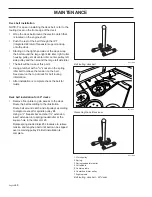

Check/adjust the mower deck

Check the engine valve clearance

4)

Perform the 300-hour service

4)

Lubricate according to Lubrication Schedule

Check hydraulic oil at reservoir

Change hydraulic oil & fi lter (200 hours)

Clean fi ns of oil cooler (Kohler)

z

z

z

z

z

z

z

z

z

z

z

MAINTENANCE

z

z

z

z

z

z

z

z

z

z

z

z

z

z

1)

First change after 5-8 hours. When operating with a heavy load or at high ambient temperatures, replace every 50 hours.

2)

In dusty

conditions, cleaning and replacement are required more often.

3)

For daily use, the machine should be lubricated twice weekly.

4)

Performed by

authorized service workshop.

z

= Described in this manual

= Not described in this manual

WARNING!

Before performing any service or adjustment checklist:

• Engage the parking brake.

• Place the Blade-switch in the disengaged position.

• Turn the ignition switch to “OFF” position and remove the key.

• Make sure the blades and all moving parts have completely stopped.

• Disconnect the spark plug wire from all spark plugs and place the wire where it

cannot come in contact with the plug.

z

z

Summary of Contents for 27 KOH/968999588

Page 2: ......

Page 67: ...English 67 WIRING DIAGRAM...

Page 79: ...English 79 SERVICE JOURNAL After the First 5 8 Hours 1 Change engine oil...

Page 85: ...English 85 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 87: ......

Page 88: ...Part No 539 131266R01 09 25 07...