18

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • 620-251-2000

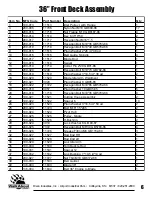

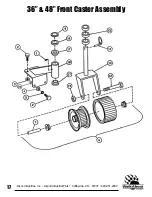

36” & 48” Front Caster Assembly

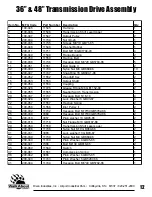

Item No. MFG Code

Part Number Description

Qty

1

200-026

11726

Grease Fitting M6 GB1152-89

4

2

200-003

12808

Hexagon Bolt M10*25 GB 5783-86

8

3

200-006

11706

Nylon Nut M10 GB889-86

4

4

200-010

3057

Plain Washer 10 GB95-85

4

5

200-031

3065

Lock Washer 10 GB93-87 (For 36")

2

6

100-092

11592

Castor Wheel Assembly W

2

7

100-093

11593

Pivot Tube, Castor

2

9

100-015

11515

Plain Washer 2*26 id *38 od

2

12

200-057

11757

Hexagon Bolt M12*140 GB5782-86

2

13

100-096

11596

Castor Yoke

2

14

100-097

11597

Lynch Pin

2

15

100-098

11598

Spacer 13

6

16

100-099

11599

Spacer 6.5

2

17

100-100

11600

Bushing, Castor

4

18

100-101

11601

Castor Support

2

19

200-007

11707

Nylon Nut M12 GB889-86

2

20

200-006

11706

Nylon Nut M10 GB889-86 (For 48")

4