21

INTERLOCK SWITCH TEST:

Note: Operator must be seated in normal operating position to

perform these tests.

1.

With engine off, turn mower blade on and attempt to

start engine.

ENGINE SHOULD NOT START.

2.

With engine off, move control levers in and attempt to

start engine.

ENGINE SHOULD NOT START

3.

In a SAFE AREA, away from bystanders, start the

engine, place throttle setting at maximum or full.

Engage the blade drive through the electric clutch

switch. Raise slightly off of seat.

ENGINE SHOULD STOP.

4.

With engine running, set parking brake and move

levers inboard.

ENGINE SHOULD STOP.

If any safety check fails, do not operate the mower until the

system has been checked and repaired by an authorized

Dixon ZTR dealer.

OPERATION INSTRUCTIONS

Summary of Contents for 8000D Series

Page 1: ...8000D SERIES 2003 OPERATOR S MANUAL...

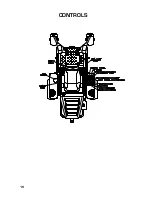

Page 18: ...18 CONTROLS...