OPERATION

Dixon-

33

English

-

33

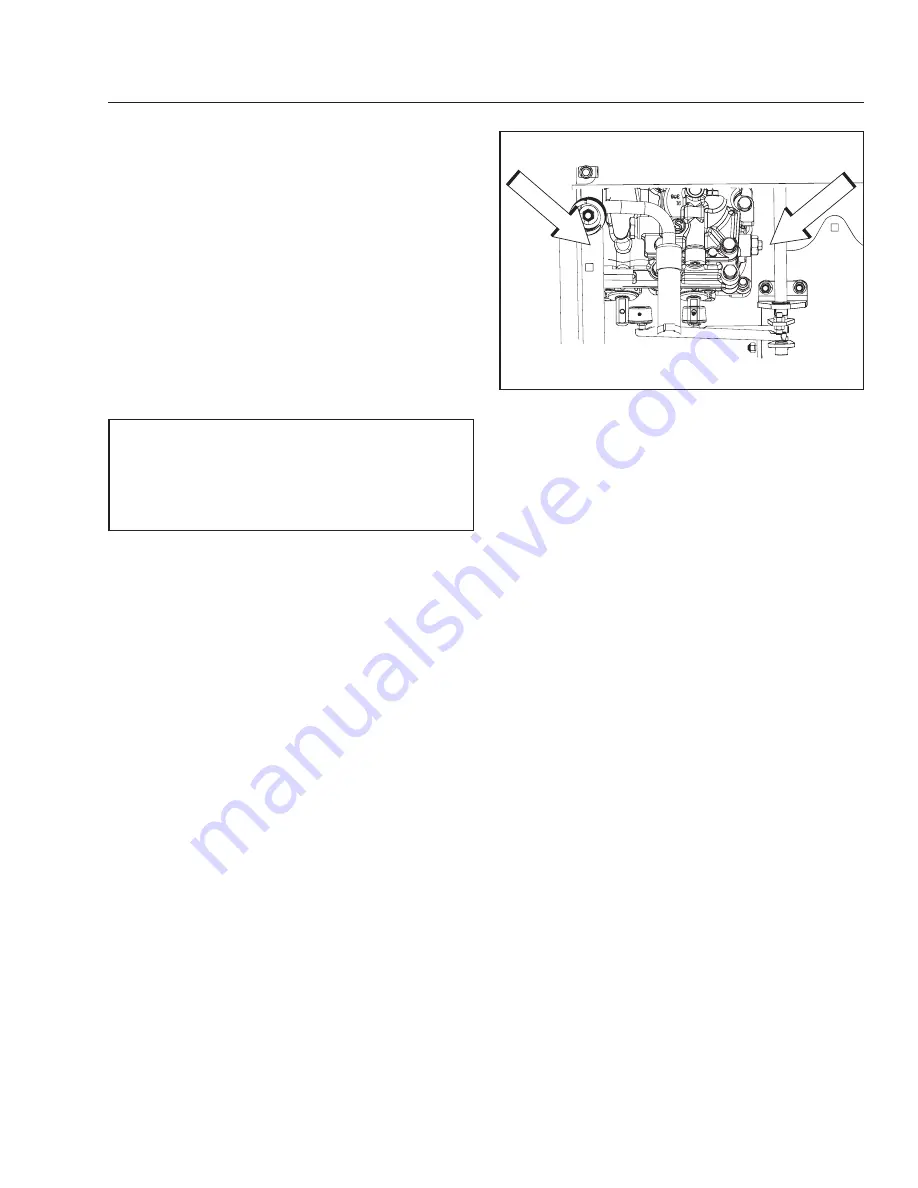

Manually Moving Unit

Pump release valves

Pump release valves are located at the front and rear

of the pump. They are used to release the system

so the machine may be moved by hand when not

running. Tilt seat forward to gain access to the pump.

The rear bypass valve sits directly opposite the front

valve, below the seat support. It is not visible in the

illustration.

Use a 17 mm open end wrench or socket and ratchet.

Turn the outer locknut 2-3 turns. Using an 8mm

wrench or socket, turn the inner nut one turn.

Reverse the procedure to reset the pump, makng sure

the outer locknut is tightened.

IMPORTANT INFORMATION

Tighten the valve moderately.

Do not overtighten the valve when closing.

That can damage the valve seat.

8011-507

Pump release valves

Summary of Contents for 965871801

Page 2: ...2008 HTC All rights reserved Beatrice NE Printed in U S A...

Page 56: ...schematics 56 Dixon...

Page 68: ...68 Dixon SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 69: ...Dixon 69 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 70: ......

Page 71: ......

Page 72: ...P N 115 126526 IR 08 16 08...