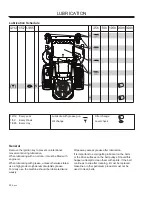

lUBRICATION

52-

dixon

IMPORTANT INFORMATION

Used engine oil is a health hazard and must

not be disposed of on the ground or in nature;

it should always be disposed of at a workshop

or appropriate disposal location.

Avoid skin contact; wash with soap and water

in case of spills.

Engine Oil

Engine Oil Filter

drain the engine oil in accordance with the work

•

description under the heading Engine Oil/Change

Engine Oil.

Remove the oil filter. If necessary, use a filter

•

remover.

Wipe new, clean engine oil onto the seal for the

•

new filter.

Mount the filter by hand with +¾ turn.

•

Run the engine warm, then check that there are

•

no leaks around the oil filter seal.

Check the oil level in the engine, fill if necessary.

•

The oil filter holds 0.1 qt (0.1 liters) of oil.

8011-734

Changing the oil filter

WARNING!

Engine oil can be very hot if it is

drained directly after stopping the

engine. Allow the engine to cool to a

safe temperature before draining.

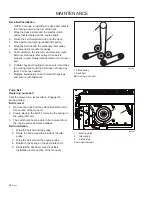

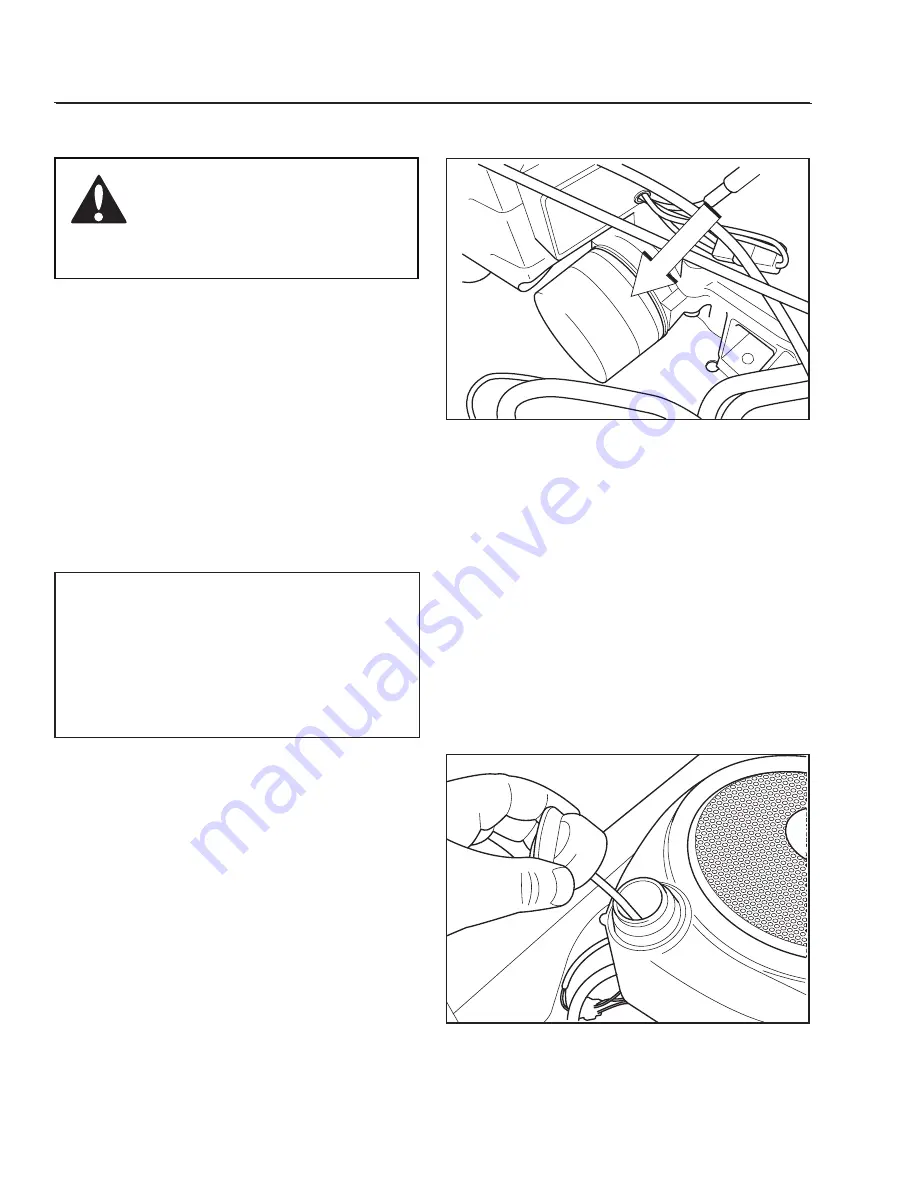

Engine Oil Levels

Check the oil level in the engine when the machine is

standing level and the engine is stopped.

Remove the dipstick, wipe it clean, and then replace it.

The dipstick should be screwed into place.

Take the dipstick out again and read the oil level.

The oil level should lie between the markings on the

dipstick. If the level is approaching the “ADD” mark, fill

the oil to the “fUll” mark on the dipstick.

Never fill to above the “FULL” mark.

The oil is filled through the hole for the dipstick.

API class Sf, SG, SH, SJ or higher must be used.

Synthetic oil SAE 5W-30 or 10W-30 is recommended

at all temperatures. Mineral oil SAE 5W-30, 10W-30

can be used between -18 °C/0 °f and +75 °C/40 °f. At

temperature above +5 °C/40 °f single grade SAE 30

must be used.

See the Technical data section for oil amounts.

8011-500

Remove the dipstick