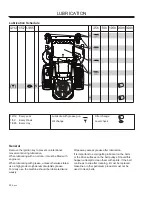

lUBRICATION

56-

dixon

Purging

Due to the effects air has on efficiency in hydrostatic

drive applications, it is critical to purge the system.

These purge procedures should be implemented

any time a hydrostatic system has been opened to

facilitate maintenance or any additional oil has been

added to the system.

Resulting symptoms in hydrostatic systems may be:

Noisy operation.

1.

lack of power or drive after short term operation.

2.

High operation temperature and excessive

3.

expansion of oil.

Shortened component life.

4.

Before starting, make sure the pump is at the proper

oil level. If not, fill to the specifications outlined prior.

The following procedures are best performed with the

vehicle drive wheels off the ground, then repeated

under normal operating conditions.

disengage the brake if activated.

1.

With the bypass valve open and the engine

2.

running at fast idle, slowly move the steering

control in both forward and reverse directions (5 or

6 times). As air is purged from the unit, the oil level

will drop.

With the bypass valve closed and the engine

3.

running, slowly move the steering control in both

forward and reverse directions (5 to 6 times).

Check the oil level and add oil as required after

stopping the engine.

It may be necessary to repeat Steps 2 and 3 until

4.

all the air is completely purged from the system.

When the transaxle operates at normal noise

levels and moves smoothly forward and reverse

at normal speeds, the transaxle is considered

purged.

After the vehicle has been used two times, the oil

5.

level should be checked while the oil is cold and

adjusted accordingly.

8058-020

Disengage the parking brake

WARNING!

Escaping hydraulic oil under

pressure can have sufficient force to

penetrate the skin, causing serious

injury.

If injured by escaping fluid,

see a doctor at once. Serious

infection or reaction can develop

if proper medical treatment is not

administered immediately.