opeRatIon

30

Engage the mower deck by pulling out the

6.

blade switch.

move throttle control to full throttle (not choke).

7.

The machine’s speed and direction are

continuously variable using the two steering

controls. When both controls are in the neutral

position, the machine stands still.

By moving both controls an equal amount

forward or backward, the machine moves in a

straight line forward or backward respectively.

In order, for example, to turn right while

moving forward, move the right control

towards the neutral position. The rotation of the

right wheel is reduced and the machine turns

to the right.

Turning on the spot can be achieved by

moving one control backward (behind the

neutral position) and carefully moving the

other steering control forward from its neutral

position.

8050-781

Set blade engagement and throttle control

IMPORTANT INFORMATION

Control levers return to neutral when released.

This may cause the mower to suddenly stop.

Operating On Hills

read

Slope Operation

in the

Safety

section.

The slowest speed possible should be used

•

before starting up or down hills.

Avoid stopping or changing speed on hills.

•

If stopping is absolutely necessary, pull drive

•

levers into the neutral position and push to the

outside of the unit and engage the parking brake.

To restart movement, release the parking brake.

•

WARNING!

Do not drive up or down hills with

slopes greater than 10 degrees. Do not

drive across slopes.

8061-020

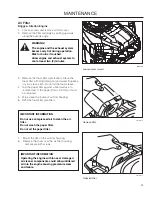

Place controls in neutral position

8058-020

Released parking brake

Pull the control levers back to the center of the

•

mower and press forward to regain forward

motion.

make all turns slowly.

•

Summary of Contents for 966038601

Page 2: ...2009 HTC All rights reserved Beatrice NE Printed in U S A...

Page 58: ...schematics 58...

Page 68: ...68 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 69: ...69 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 70: ...70 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 71: ......

Page 72: ...P N 115 294527R1 09 21 09...