Problem

Cause

Engine will not start

Blade switch is engaged.

•

Steering controls are not locked in the neutral position

•

Driver is not sitting in the driver’s seat

•

Parking brake is not activated

•

Battery is dead

•

Contamination in the carburetor or fuel line.

•

fuel supply is closed or the shutoff valve for the fuel tank is in

•

the wrong position

Clogged fuel filter or fuel line

•

Ignition system faulty

•

Starter does not turn the engine over

Battery is dead

•

Poor contact of the battery terminal cable connections

•

Blown fuse

•

fault in the starter safety circuit. See Checking the Safety

•

System in the “maintenance Section”

Engine runs rough

faulty carburetor

•

Choke control is pulled out with a warm engine

•

Clogged fuel filter or jet

•

Clogged ventilation valve on the fuel cap

•

fuel tank nearly empty

•

fouled spark plugs

•

Rich fuel mixture or fuel-air mixture.

•

Wrong fuel type

•

Water in fuel

•

Clogged air filter

•

Engine seems weak

Clogged air filter

•

fouled spark plugs

•

Carburetor incorrectly adjusted

•

Air trapped in hydraulic system

•

machine vibrates

Blades are loose

•

Blades are incorrectly balanced

•

Engine is loose

•

tRoUblesHootInG

48

Summary of Contents for 966057501

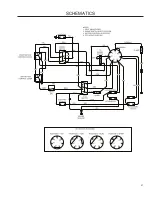

Page 51: ...schematics 51...

Page 60: ...60 Action Date mtr reading stamp sign SERVICE JOURNAL...

Page 61: ...61 Action Date mtr reading stamp sign SERVICE JOURNAL...

Page 62: ...62 Action Date mtr reading stamp sign SERVICE JOURNAL...

Page 63: ......

Page 64: ...P N 115 248226R1 01 28 10...