OpERATION

25

8050-900

Blade switch

8058-019

Cut height lift lever

8058-092

Released parking brake

Before Starting

Read the sections Safety Instructions and

•

Controls before starting the machine.

Perform the daily maintenance before

•

starting (see Maintenance Schedule in the

Maintenance section).

Check that there is sufficient fuel in the fuel

•

tank.

Adjust the seat to the desired position.

•

The following conditions must be fulfilled before the

engine can be started:

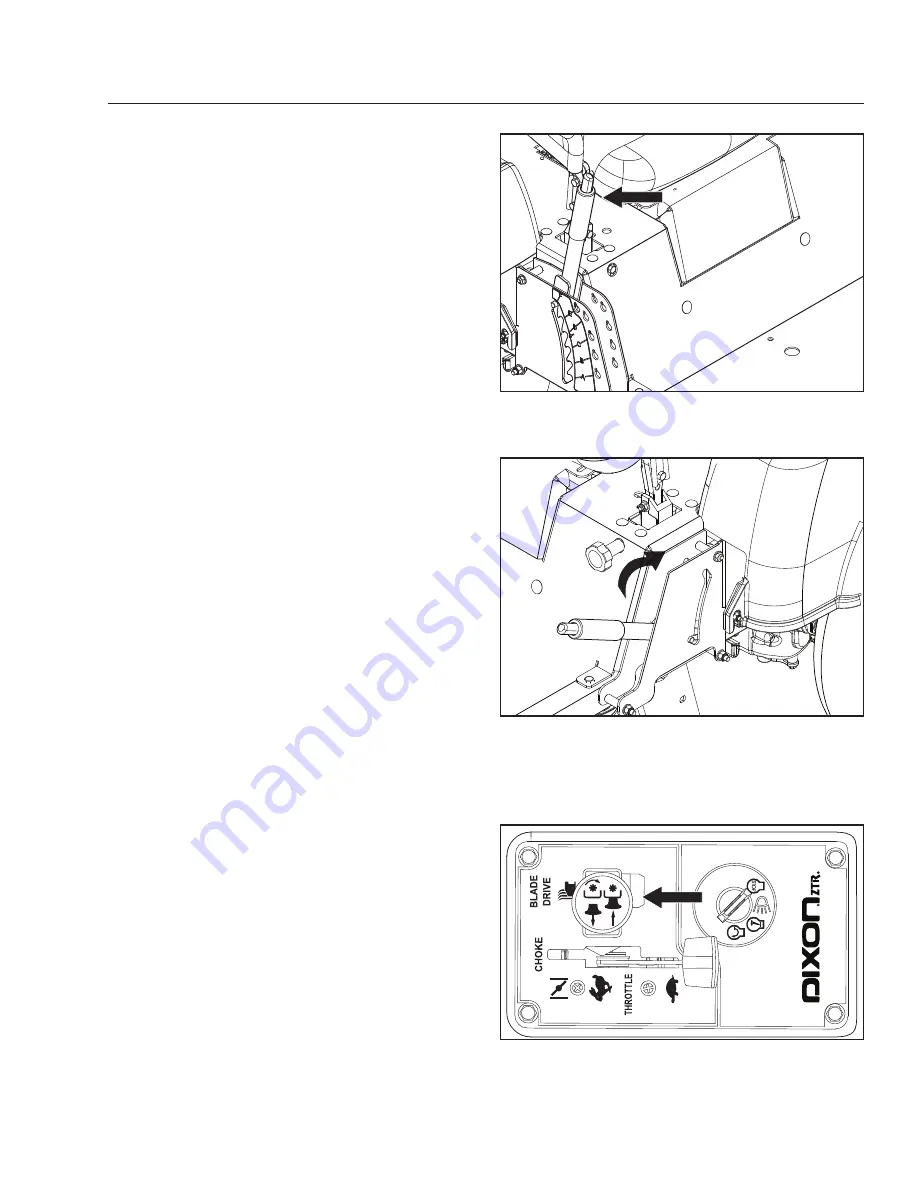

The blade switch for engaging the mower

•

blades must be depressed.

The parking brake must be on.

•

Both steering controls must be in the locked

•

(outer) neutral position.

Starting the Engine

Sit on the seat.

•

Raise the mower deck by pushing the release

•

button on the top of the lifting lever. Pull the lifting

lever backward to the locked (transport) position.

Activate the parking brake by pushing the release

•

button in and pulling the lever fully upwards.

Disengage the mower blades by depressing the

blade switch.