2

1

3

mAINTENANCE

40

IMPORTANT INFORMATION

Special blade bolt is heat treated.

Replace with a Dixon bolt if required.

Do not use lower grade hardware than

specified.

Cutting Blades

To attain the best mowing effect, it is important that

the blades are well sharpened and not damaged.

Bent or cracked blades or blades with large nicks

should be replaced.

IMPORTANT INFORMATION

The sharpening of blades should be carried

out by an authorized service workshop.

WARNING!

Blades are sharp. Protect your hands

with gloves and/or wrap blades with

a heavy cloth when handling.

Damaged blades should be replaced after hitting

obstacles that result in a breakdown. A service

workshop should decide whether the blade can be

repaired/ground or must be replaced. Balance the

blades after sharpening and check the blade mounts.

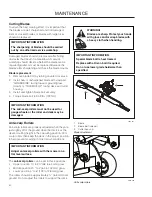

Blade replacement

Remove blade bolt by turning counter clockwise.

1.

Install new or resharpened blade with stamped

2.

“GRASS SIDE” facing towards ground/grass

(down) or “THIS SIDE UP” facing deck and cutter

housing.

Install and tighten blade bolt securely.

3.

Torque blade bolt to 90 ft/lbs (122 Nm).

4.

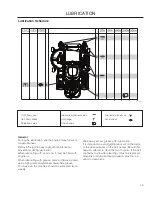

Anti-scalp Rollers

Anti-scalp rollers are properly adjusted when they are

just slightly off of the ground when the deck is at the

desired cutting height in the operating position. Anti-

scalp rollers then keep the deck in the proper position

to help prevent scalping in most terrain conditions.

IMPORTANT INFORMATION

Adjust anti-scalp rollers with the mower on a

flat level surface.

The

anti-scalp rollers

can be set in three positions:

Upper position 1½ to 2½" (38 to 64 mm) grass

•

Middle position 2½" to 4" (64 to 102 mm) grass

•

Lower position 4" to 6" (102 to 128 mm) grass.

•

The rollers should be approximately ¼" (6.5 mm) from

ground. Do not adjust the rollers to support the deck.

IMPORTANT INFORMATION

The anti-scalp rollers must not be used for

gauge wheels or the roller and deck may be

damaged.

8050-830

Anti-scalp rollers

8058-027

Blade

1.

Blade bolt (special)

2.

Cutter housing

3.

Blade attachment