CONTROLS

17

This operator’s manual describes the Dixon Zero Turn

Rider. The rider is fitted with a four-stroke overhead

valve engine.

Transmission from the engine is made via belt-driven

hydraulic pumps. Using the left and right steering

controls, the flow is regulated and thereby the

direction and speed.

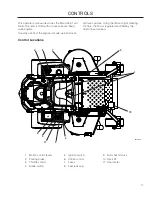

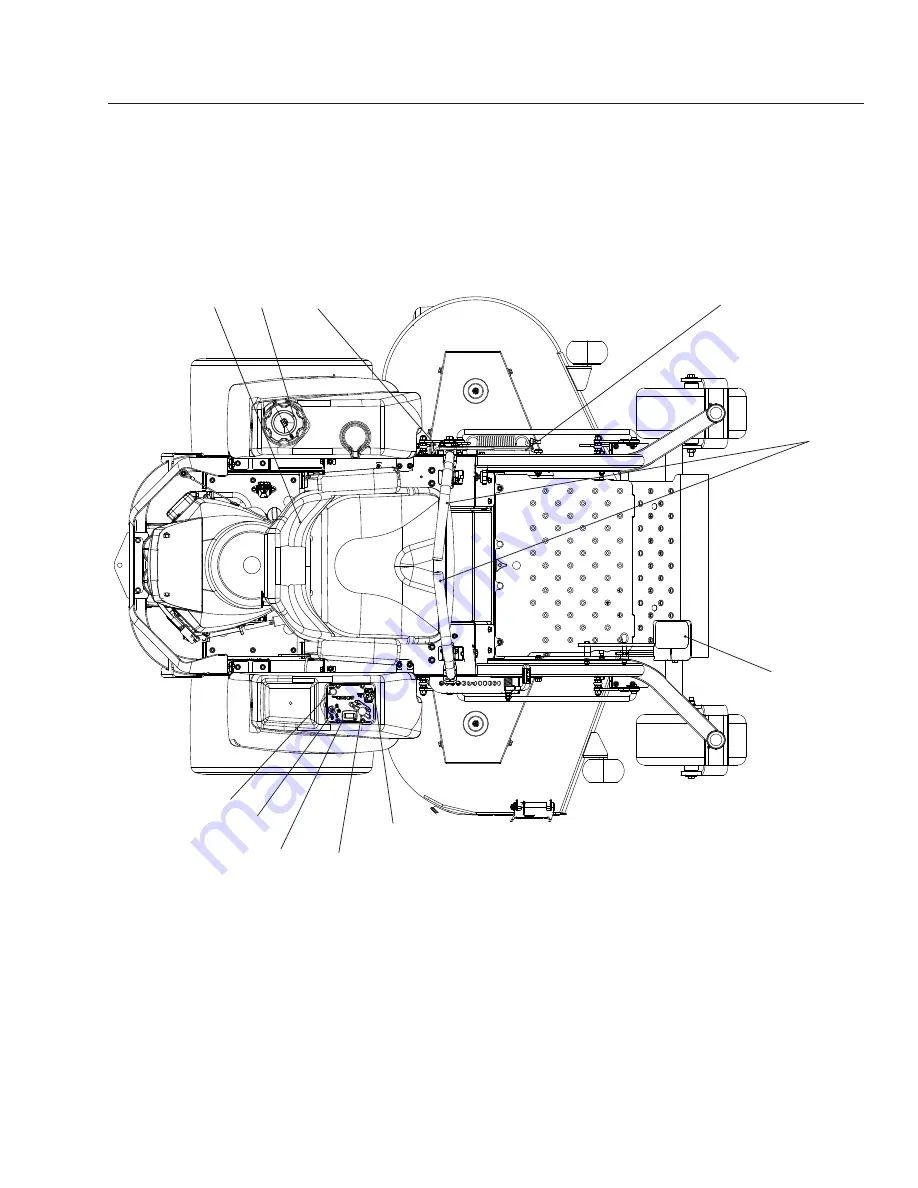

Control Locations

8050-080

1. Motion control levers

2. Parking brake

3. Throttle control

4. Blade switch

5. Ignition switch

6. Choke control

7. Fuses

8. Fuel tank cap

9. Fuel shut off valve

10. Deck lift

11. Hour meter

1

2

6

10

9

8

4

5

11

7

3

Summary of Contents for 966690603

Page 51: ...51 SCHEMATIC 8053 002...

Page 60: ......