45

lUbRICatIon

Wheel and Deck Zerks

Use only good quality bearing grease.

Grease from well-known brand names (petrochemical

companies, etc.) usually maintains a good quality.

Front Wheel Mount

Lubricate 3-4 strokes with a grease gun on each set of

wheel bearings.

Front Wheel Bearings

Lubricate 3-4 strokes with a grease gun on each set of

wheel bearings.

8058-068

Lubricating the front wheels

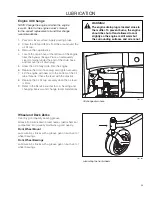

Engine Oil Change

NOTE: Change the engine oil when the engine

is warm. Refer to the engine owner’s manual

for the correct replacement oil and filter change

recommendations.

WARNING!

The engine drain plug is located close to

the muffler. To prevent burns, the engine

should be shut off and allowed to cool

slightly so the engine is still warm but

the surrounding surfaces and oil are not.

1. Park on a level surface. Apply parking brake.

2. Clean the dirt and debris from the area around the

oil fill cap.

3. Remove the cap/dipstick.

4. Locate the drain hose at the left rear of the engine

near the bypass linkage. Place an adequately

sized container under the end of the drain hose

and remove the oil drain plug.

5. Allow the oil to fully drain from the engine.

6. Replace the drain hose plug and tighten securely.

7. Fill the engine with new oil to the bottom of the fill

tube threads. Check the level with the dipstick.

8. Replace the oil fill cap securely when the oil level

is FULL.

9. Refer to the Service Journal for oil checking and

changing intervals and change recommendations

8058-216

Oil change drain hose

Summary of Contents for 966698603

Page 50: ...50 schematics...

Page 58: ...58 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 59: ......

Page 60: ......