MAIntenAnCe

37

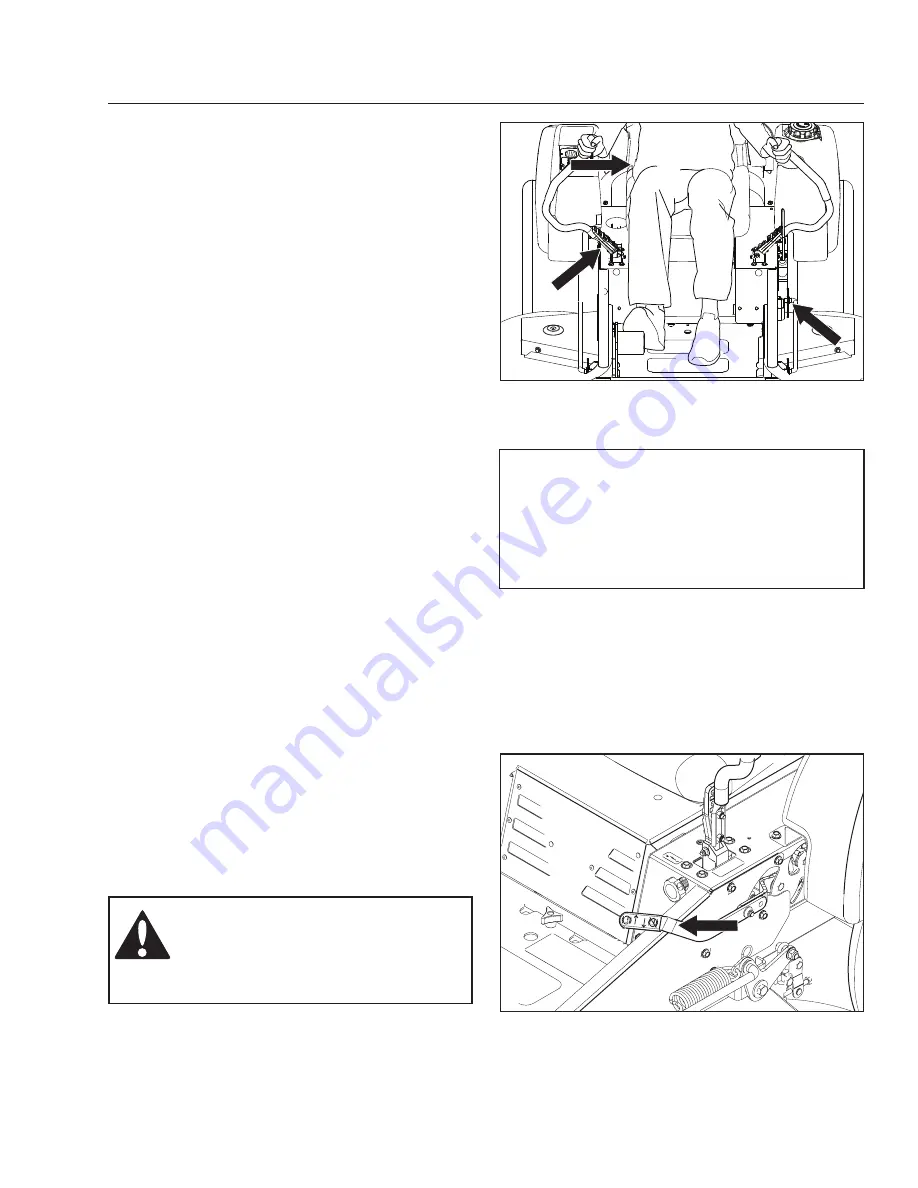

Safety System

The machine is equipped with a safety system that

prevents starting or driving under the following

conditions.

The engine can only be started when:

1. The mower deck is disengaged.

2. The steering controls are in the outer, locked

neutral position.

3. The driver is sitting in the driver’s seat.

4. The parking brake is on.

Make daily inspections to ensure that the safety

system works by attempting to start the engine

when one of the conditions is not met. Change the

conditions and try again.

If the machine starts when one of these conditions

is not met, turn the machine off and repair the safety

system before using the machine again.

Make sure the engine stops when the park brake

is not engaged and the operator leaves the seated

position.

Check that the engine stops if the mower blades are

engaged and the driver temporarily moves off the

drivers seat.

IMPORTANT INFORMATION

In order to be able to drive, the driver must

sit in the seat and release the parking brake

before the steering controls can be moved into

the neutral position, otherwise the engine will

stop.

8050-913

Start conditions

Tire Pressures

All tires should be at 15 psi / 103 kPa / 1 bar.

Parking Brake

Visually check that no damage is found on the lever,

links, or switch belonging to the parking brake.

Perform a standstill test and check that there is

sufficient braking action.

To adjust the parking brake, contact the Dixon service

workshop.

WARNING!

Faulty adjustment can result in reduced

braking ability and can cause an

accident.

8061-010

Check for proper operation of parking brake

Summary of Contents for 966985401

Page 50: ...50 SCHEMATIC 8053 002...

Page 60: ...60 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 61: ...61 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 62: ...62 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 63: ......

Page 64: ...P N 115 354727R1 01 06 10...