2

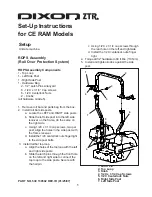

Control Arms

Remove top bolt in control arm and loosen bot-

tom bolt, rotate the control levers to the upright

position. Align the levers so they are even in the

neutral position. Reinstall hardware and tighten.

FIG - 1

Seat Install

1. Remove seat assembly from the crate.

2. Remove the four 5/16C nyloc nuts or 5/16C

studded knobs from the bottom of the seat.

Retain for use later.

3. Align the seat bottom with the holes in the seat

frame. Place seat on top of the seat frame

and secure with the four nuts or knobs re-

moved in step 2.

4. Connect the wire harness from the seat to the

frame harness.

5. Install armrests to seat. Hardware and arm-

rests are in the plastic bag.

Engine Oil

Check engine oil with dip stick. Add if needed per

the engine manufacturer’s specifications. See en-

gine manual for oil type and filling specifications.

FIG - 2

Loosen the discharge chute slightly and lower into

position. Chute should be snug but still pivot freely.

FIG - 1

FIG - 2

FIG - 3

Discharge Chute

If discharge chute is not assembled to the cutting

deck follow the instructions below.

1. Hook the spring end over the discharge chute

and align the internal diameter of the spring

with the holes in the chute.

2. Align the chute and spring with the tabs on the

cutting deck. Rotate the spring end counter-

clockwise so it rests on top of the cutting deck.

3. Slide the clevis pin with a 5/16 washer through

the holes of the chute, deck and spring.

4. Secure clevis pin with 5/16 washer and cotter

pin.

5. If assembled properly the chute should be

spring loaded in the down position. FIG - 3

Mount rear drive wheels using the lug nuts installed

on the hubs.

Check the tire pressure in all four tires. All tires

should be 15 psi.

Tires

1. Motion Control Lever

2. Control Arm

1. Operating Range

2. “F” Full Mark

1

2

3

4

5

1

2

1

2

1. Discharge Chute

2. 5/16 Washer

3. Clevis Pin

4. 1/2 X 3/4 Cotter Pin

5. Spring