English

-

37

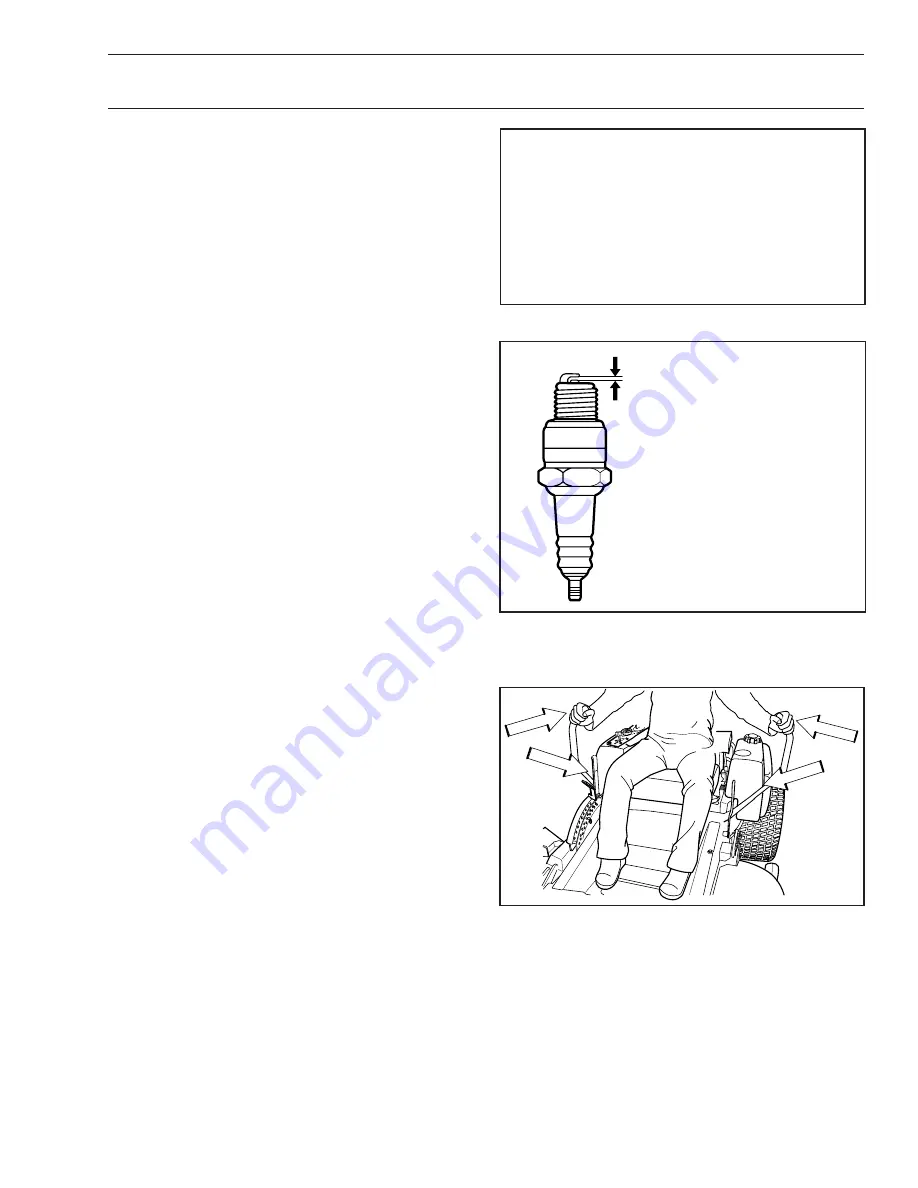

Ignition System

The engine is equipped with an electronic ignition

system. Only the spark plug requires maintenance.

For recommended spark plug, see Technical Data.

1. Remove the ignition cable boot and clean

around the spark plug.

2. Remove the spark plug with a spark plug

socket wrench.

3. Check the spark plug. Replace the spark

plug if fouled, the electrodes are burned and

if the insulation is cracked or damaged.

Clean the spark plug with a steel brush if it is

to be reused.

4. Measure the electrode gap with a gapping

tool. The gap should be .030" (0.75 mm).

Adjust as necessary by bending the side

electrode.

5. Reinsert the spark plug, turning by hand to

avoid damaging the threads.

6. After the spark plug is seated, tighten it using

a spark plug wrench so that the washer is

compressed. A used spark plug should be

turned

1

/

8

of a turn from the seated position.

A new spark plug should be turned ¼ turn

from the seated position.

7. Replace the ignition cable.

Checking the Safety System

The machine is equipped with a safety system that

prevents starting or driving under the following

conditions.

The engine can only be started when:

• The mower deck is disengaged.

• The steering controls are in the outer, locked

neutral position.

• The driver is sitting in the driver’s seat.

• The parking brake is on.

Make daily inspections to ensure that the safety

system works by attempting to start the engine when

one of the conditions is not met. Change the

conditions and try again.

If the machine starts when one of these conditions is

not met, turn the machine off and repair the safety

system before using the machine again.

1. Make sure the engine stops when the

parking brake is not engaged and the

operator leaves the seated position.

2. Check that the engine stops if the mower

blades are engaged and the driver

temporarily stands up.

IMPORTANT INFORMATION

Fitting the wrong spark plug type can

damage the engine.

Inadequately tightened spark plug can

cause overheating and damage the engine.

Tightening the spark plug too hard can

damage the threads in the cylinder head.

Measure the electrode gap

8011-054

0.028-0.031 in

(0.70-0.80 mm)

Starting conditions

8050-801

MAINTENANCE