12

TOWING CARTS AND OTHER AT TACH MENTS

Tow only the attachments that are recommended by and

comply with specifications of the manufacturer of your trac-

tor. Use common sense when towing. Too heavy of a load,

while on a slope, is dangerous. Tires can lose traction with

the ground and cause you to lose control of your tractor.

TRANSMISSION ENGAGED

TRANSMISSION DISENGAGED

02203

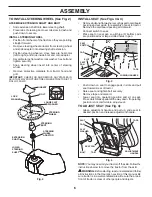

Fig. 14

TO TRANSPORT (See Fig. 14)

When push ing or tow ing your trac tor, ensure transmission

is disengaged by placing freewheel control in free wheel ing

po si tion. Free wheel control is located at the rear drawbar

of tractor.

•

Raise attachment lift to highest position with at tach ment

lift control.

•

Pull freewheel control out and into the slot and release

so it is held in the disengaged position.

• Do not push or tow tractor at more than two (2) mph

(3,2 km/h).

• To reengage transmission, reverse above procedure.

NOTE

: To protect hood from damage when transporting

your tractor on a truck or a trailer, ensure hood is closed

and secured to tractor. Use an appropriate means of tying

hood to tractor (rope, cord, etc.).

TO OPERATE ON HILLS

CAUTION: Do not drive up or down hills

with slopes greater than 15° and do not

drive across any slope.

• Choose the slowest speed before starting up or down

hills.

• Avoid stopping or changing speed on hills.

• If stopping is absolutely necessary, push brake pedal

quickly to brake position and engage parking brake.

•

To restart movement, slowly release parking brake and

brake pedal.

•

Slowly depress appropriate drive pedal to slowest set-

ting.

• Make all turns slowly.

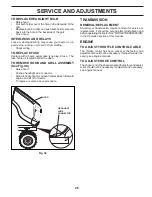

ROS "ON"

POSITION

ENGINE "ON" POSITION

(NORMAL OPERATING)

02828

Fig. 13

OPERATION

REVERSE OPERATION SYSTEM (ROS)

Your tractor is equipped with a Reverse Operation System

(ROS). Any attempt by the operator to travel in the reverse

direction with the attachment clutch engaged will shut off

the engine unless ignition key is placed in the ROS "ON"

position.

WARNING:

Backing up with the attachment clutch en-

gaged while mowing is strongly discouraged. Turning the

ROS "ON", to allow reverse operation with the attachment

clutch engaged, should only be done when the operator

decides it is necessary to reposition the machine with the

attachment engaged.

Do not mow in reverse unless

absolutely necessary

.

USING THE REVERSE OPERATION SYSTEM (See Fig. 13)

Only use if you are certain no children or other bystanders

will enter the mowing area.

• Depress brake pedal all the way down.

•

With engine running, turn ignition key counterclockwise

to ROS "ON" position.

• Look down and behind before and while backing.

•

Slowly depress reverse drive pedal to start movement.

• When use of the ROS is no longer needed, turn the

ignition key clockwise to engine "ON" position.

BEFORE STARTING THE ENGINE

CHECK ENGINE OIL LEVEL

The engine in your tractor has been shipped from the fac-

tory already filled with sum mer weight oil.

• Check engine oil with tractor on level ground.

• Unthread and remove oil fill cap/dipstick; wipe oil off.

Reinsert the dipstick into the tube and rest oil fill cap

on the tube. Do not thread the cap onto the tube.

Remove and read oil level. If necessary, add oil until

“FULL” mark on dipstick is reached. Do not overfill.

• For cold weather operation you should change oil for

easier starting. (See “OIL VISCOSITY CHART” in the

Maintenance sec tion of this manual.)

• To change engine oil, see the Maintenance section in

this manual.

Summary of Contents for D15KH30

Page 29: ...29 SERVICE NOTES...

Page 30: ...30 SERVICE NOTES...