22

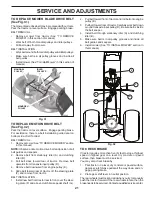

TO REMOVE WHEEL (See Fig. 34)

• Block up axle securely.

•

Remove axle cover, retaining ring and washers to allow

wheel removal (rear wheel contains a square key - Do

not lose).

• Repair tire and reassemble.

• On rear wheels only: align grooves in rear wheel hub

and axle. Insert square key.

• Replace washers and snap retaining ring securely in

axle groove.

• Replace axle cover.

NOTE:

To seal tire punctures and prevent flat tires due to

slow leaks, tire sealant may be purchased from your local

parts dealer. Tire sealant also prevents tire dry rot and

corrosion.

Fig. 34

RE TAIN ING

RING

WASH ERS

SQUARE KEY (REAR

WHEEL ONLY)

AXLE

COVER

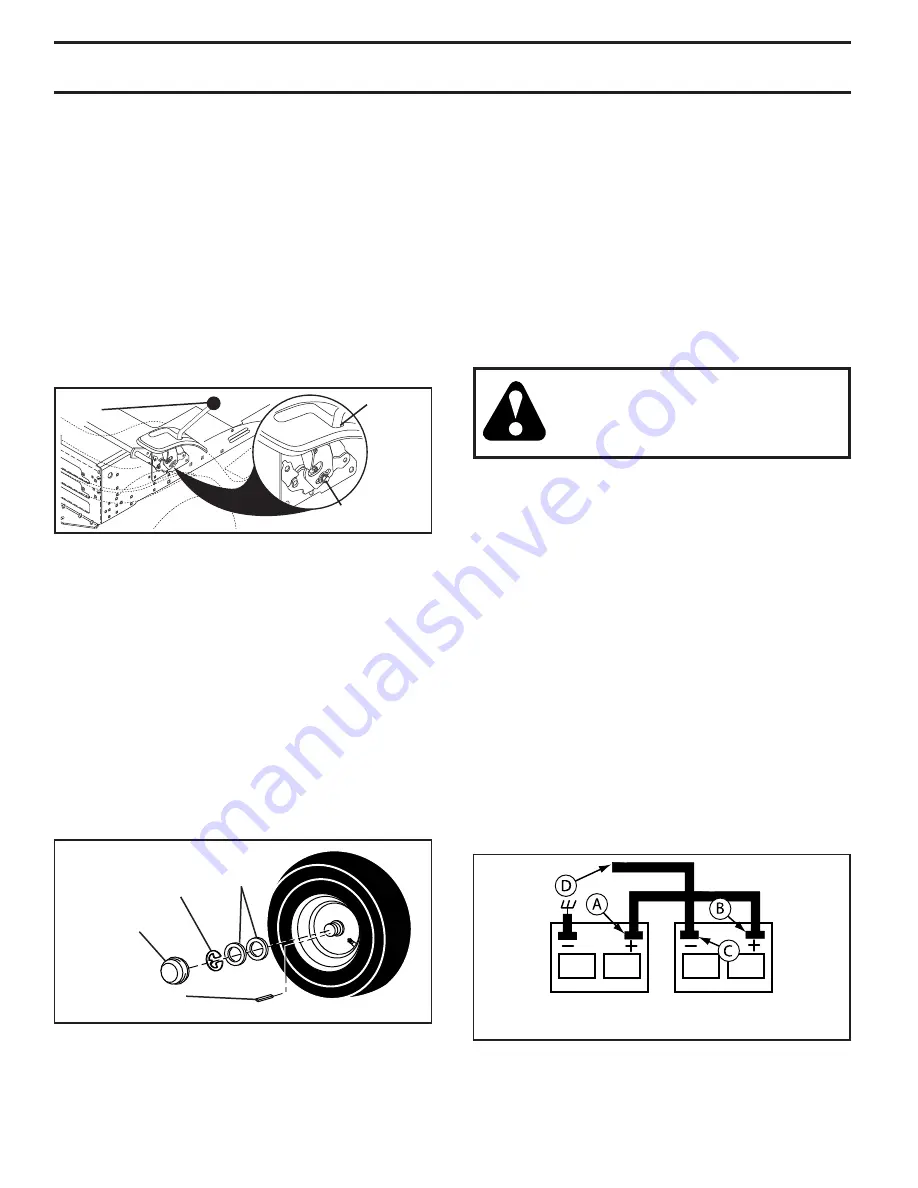

TO START ENGINE WITH A WEAK BATTERY

(See Fig. 35)

WARNING

:

Lead-acid batteries gen er-

ate ex plo sive gases. Keep sparks,

flame and smoking ma te ri als away from

bat ter ies. Always wear eye pro tec tion

when around batteries.

If your battery is too weak to start the engine, it should be

recharged. (See "BATTERY" in the Maintenance sec tion

of this man u al).

If “jumper ca bles” are used for emer gen cy starting, follow

this pro ce dure:

IMPORTANT

: YOUR TRACTOR IS EQUIPPED WITH A 12 VOLT

SYSTEM. THE OTHER VEHICLE MUST ALSO BE A 12 VOLT

SYSTEM. DO NOT USE YOUR TRACTOR BATTERY TO START

OTHER VEHICLES.

TO ATTACH JUMPER CABLES -

• Connect one end of the RED cable to the POSITIVE

(+) terminal of each battery(A-B), taking care not to

short against tractor chassis.

•

Connect one end of the BLACK ca ble to the NEGA TIVE

(-) terminal (C) of fully charged battery.

•

Connect the other end of the BLACK cable (D) to good

chassis ground, away from fuel tank and bat tery.

TO REMOVE CABLES, REVERSE ORDER -

•

BLACK cable first from chassis and then from the fully

charged battery.

• RED cable last from both batteries.

Fig. 35

WEAK OR DEAD

BATTERY

FULLY CHARGED

BATTERY

TO AD JUST STEER ING WHEEL ALIGN MENT

If steering wheel crossbars are not horizontal (left to right)

when wheels are positioned straight forward, remove steer-

ing wheel and reassemble per instructions in the Assembly

section of this manual.

FRONT WHEEL TOE-IN/CAMBER

Your new tractor front wheel toe-in and camber is set at the

factory and is normal. The front wheel toe-in and camber

are not adjustable. If damage has occurred to affect the

factory set front wheel toe-in or camber, contact a qualified

service center.

TRANSAXLE GEAR SHIFT LEVER NEU TRAL

ADJUSTMENT (See Fig. 33)

The transaxle should be in neutral when the gear shift lever is

in neutral (lock gate) position. The adjustment is preset at the

factory; however, if adjustment is needed, proceed as follows:

• Make sure transaxle is in neutral.

NOTE:

When the tractor rear wheels move freely, the

transaxle is in neutral.

• Loosen adjustment bolt in front of the right rear

wheel.

• Position the gear shift lever in the neutral position.

• Tighten adjustment bolt securely.

NOTE:

If additional clearance is needed to get to ad just ment

bolt, move mower deck height to the lowest position.

GEARSHIFT

LEVER

ADJUSTMENT

BOLT

NEUTRAL

LOCK

GATE

Fig. 33

SERVICE AND ADJUSTMENTS