6

TO REMOVE TRACTOR FROM CARTON

UNPACK CARTON

• Remove all accessible loose parts and parts cartons

from carton .

• Cut along dotted lines on all four panels of carton.

Remove end panels and lay side panels flat.

• Remove mower and packing materials.

• Check for any additional loose parts or cartons and

remove.

BEFORE REMOVING TRACTOR FROM

SKID

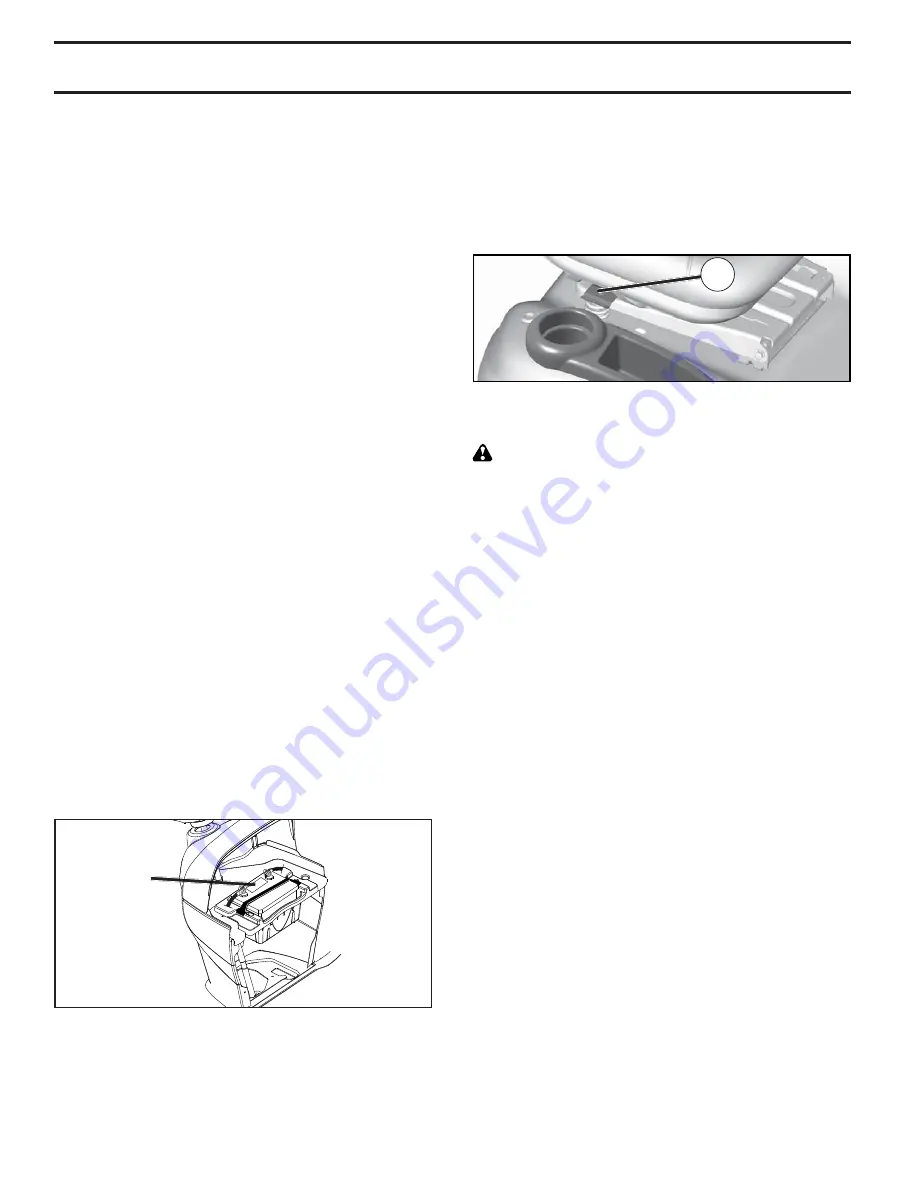

TO CHECK BATTERY (See Fig. 1)

• Lift hood to raised position.

NOTE:

If this battery is put into service after month and

year indicated on label (label is located between terminals)

charge battery for minimum of one hour at 6-10 amps.

(See "BATTERY" in Maintenance section of this manual

for charging instructions).

• For battery and battery cable installation see "RE-

PLACING BATTERY" in the "Service and Adjustments"

section in this manual.

Fig. 1

LABEL

ADJUST SEAT (See Fig. 2)

• Sit in seat.

•

Lift up adjustment lever (A) and slide seat until a com-

fortable position is reached which allows you to press

clutch/brake pedal all the way down.

• Release lever to lock seat in position.

Fig. 2

NOTE:

You may now roll your tractor off the skid. Follow the

instructions below to remove the tractor from the skid.

WARNING:

Before start ing, read, un der stand and fol low

all in struc tions in the Op er a tion section of this man u al. Be

sure tractor is in a well-ventilated area. Be sure the area in

front of tractor is clear of other peo ple and objects.

TO ROLL TRACTOR OFF SKID (See Op er a tion

section for location and function of con trols)

• Raise attachment lift lever to its highest po si tion.

• Release parking brake by de press ing clutch/brake

ped al.

• Place freewheel control in "trans mis sion dis en gaged"

position (See “TO TRANS PORT” in the Op er a tion

section of this manual).

• Roll tractor forward off skid.

Continue with the instructions that follow.

A

ASSEMBLY

Your new tractor has been assembled at the factory with exception of those parts left unassembled for shipping purposes.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Stan dard

wrench sizes are listed.

(1) 1/2" wrench

Tire pressure gauge

(2) 7/16" wrenches

Utility knife

Pliers

When right or left hand is mentioned in this man ual, it means

when you are in the operating po si tion (seated be hind the

steer ing wheel).

CHECK TIRE PRESSURE

The tires on your tractor were overinflated at the factory

for shipping purposes. Correct tire pressure is important

for best cutting performance.

• Reduce tire pressure to PSI shown on tires.

CHECK DECK LEVELNESS

For best cutting results, mower housing should be properly

leveled. See “TO LEVEL MOWER HOUSING” in the Service

and Adjustments section of this manual.

CHECK FOR PROPER POSITION OF ALL

BELTS

See the figures that are shown for replacing motion and

mower blade drive belts in the Service and Adjustments

sec tion of this manual. Verify that the belts are routed

cor rect ly.

CHECK BRAKE SYSTEM

After you learn how to operate your tractor, check to see that

the brake is operating properly. See “TO CHECK BRAKE”

in the Service and Adjustments section of this manual.