20

SERVICE AND ADJUSTMENTS

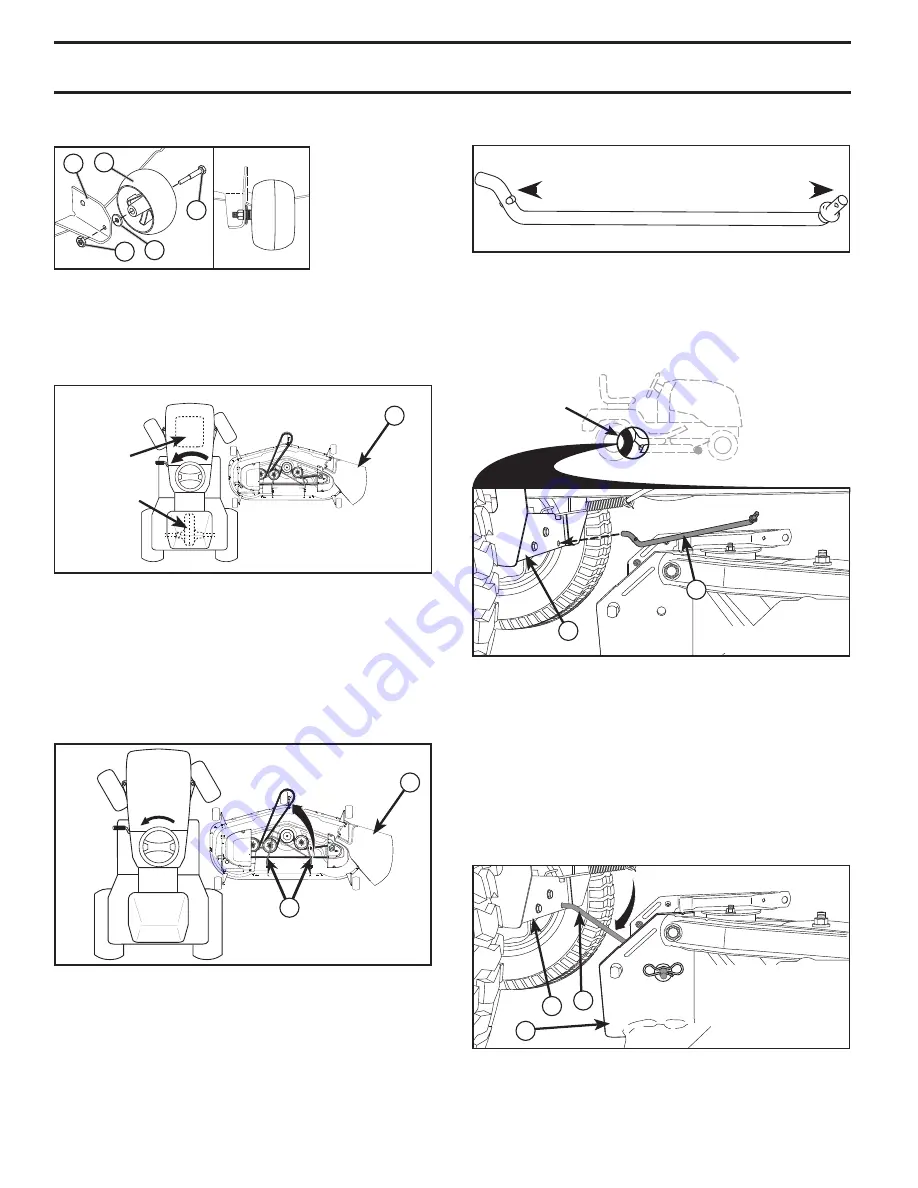

TRANSAXLE

02965

FRONT

BACK

ENGINE

Q. DEFLECTOR

SHIELD

Q

Fig. 24

90° END

INTEGRATED WASHER END

ANTI-SWAY BAR (S)

TOWARDS TOWARDS

TRANSAXLE MOWER

DECK

5. INSTALL ANTI-SWAY BAR (S) (IF EQUIPPED)

(See Fig. 26 - 28)

Fig. 26

02965

A. MOWER SIDE

SUSPENSION

ARMS

Q. DEFLECTOR

SHIELD

Q

A

Fig. 25

4. SLIDE MOWER UNDER TRACTOR (See Fig. 25)

• Bring belt forward and check belt for proper routing in

all mower pulley grooves.

NOTE

: Be sure mower side suspension arms (A) are point-

ing forward before sliding mower under tractor.

• Slide mower under tractor until it is centered under

tractor.

H. FRONT MOWER

BRACKET

W. FRONT GAUGE

WHEEL

X. SHOULDER

BOLT

Y. 1-1/4 O.D.

WASHER

Z. 3/8-16 LOCKNUT

Fig. 23

Y

Z

W

H

X

3. TURN STEERING WHEEL LEFT AND POSITION

MOWER (See Fig. 24)

• Turn steering wheel to the left as far as it will go and

position mower on right side of tractor with deflector

shield (Q) to the right.

2. ASSEMBLE FRONT GAUGE WHEEL (W) TO FRONT

OF MOWER (See Fig. 23)

NOTE

: Depending on model, bracket (T) may be differ-

ent than shown but hole for anti-sway bar will be in same

position/location.

• From right side of mower, first insert 90° end of anti-sway

bar (S) into hole in transaxle bracket (T), located near

left rear tire in front of transaxle.

NOTE

: Flashlight may be helpful.

ANTI-SWAY BAR

(S) LOCATION

TRANSAXLE

BRACKET (T)

LOCATED

BETWEEN REAR

TIRES

PLACE 9

0° END I

NTO HO

LE

PLACE 90° END INTO HOLE

S

T

S. ANTI-SWAY BAR

T. TRANSAXLE BRACKET

Fig. 27

S

D

T

D. RIGHT SIDE

REAR MOWER

BRACKET

S. ANTI-SWAY BAR

T. TRANSAXLE

BRACKET

Fig. 28

• Pivot the integrated washer end of anti-sway bar (S)

towards mower deck bracket on right side of mower.

Insert integrated washer end of bar into hole in rear

mower bracket (D). Move mower as needed to insert

integrated washer end of bar into rear mower bracket (D).

• Secure with small washer and small retainer spring as

shown.