opeRatIon

32

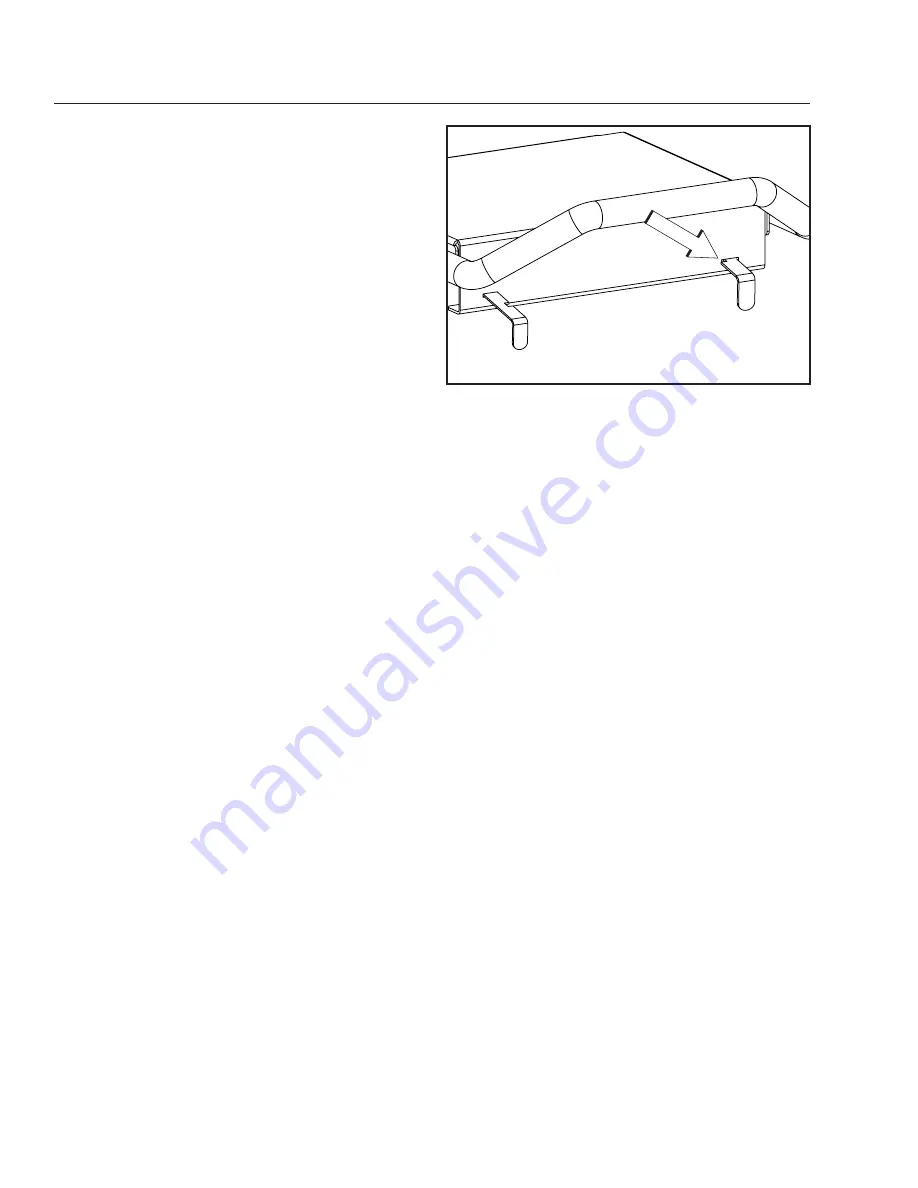

Manual Transport

When pushing or pulling the mower, be sure to

engage the EZT Hydrogear bypass linkages. The EZT

bypass linkages are located on the rear of the frame,

below the rear engine guard.

Raise the deck into the highest cutting position.

•

Pull the EZT bypass linkages out and into the

•

slots. Release linkages to hold in the bypass

position.

Release park brake.

•

To reengage the EZT’s to drive, reverse the

•

above procedure.

8050-018

Set bypass linkages into slots on both sides

Summary of Contents for SPDZTR 30 BF

Page 47: ...schematics 47 8050 050...

Page 57: ...57 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 58: ...58 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 59: ......

Page 60: ...P N 115 161527R2 09 25 09...