35

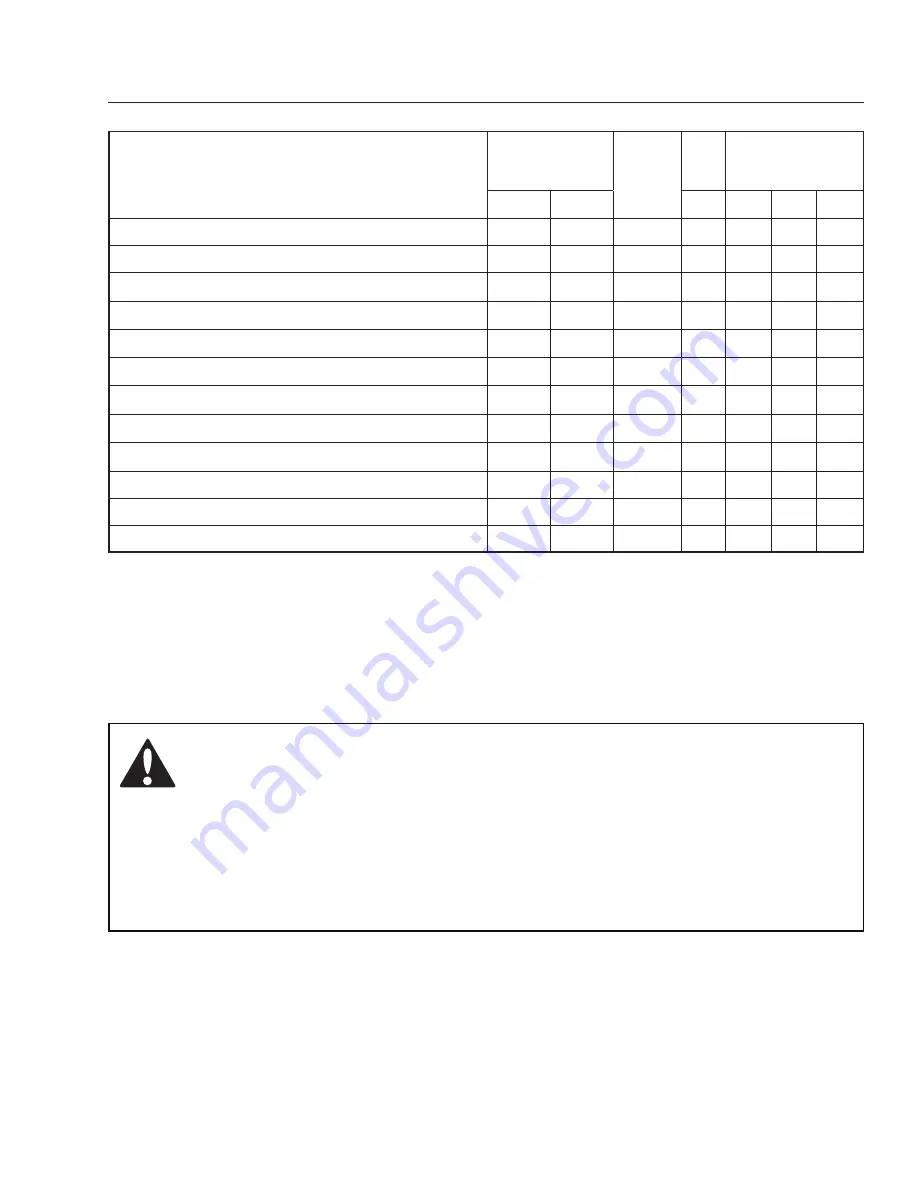

mAIntenAnCe

WARNING!

Before performing any service or adjustment checklist

• Engage the parking brake.

• Place the Blade-switch in the disengaged position.

• Turn the ignition switch to “OFF” position and remove the key.

• Make sure the blades and all moving parts have completely stopped.

• Disconnect the spark plug wire from all spark plugs and place the wire where it

cannot come in contact with the plug.

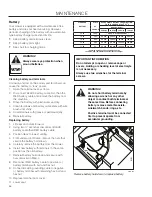

1)

first change after 5-8 hours. When operating with a heavy load or at high ambient temperatures, replace every 50 hours.

2)

In dusty

conditions, cleaning and replacement are required more often.

3)

Performed by authorized service workshop.

●

= Described in this manual

♦

= not described in this manual

■

= Refer to the engine manufacturer's manual

MAINTENANCE

Daily

At least

once

each

year

Maintenance

interval

in hours

Before After

25

50

100

300

Check/adjust throttle cable

■

Check the condition of belts, belt pulleys

●

●

Change the engine oil

1)

■

■

Replace the engine oil filter

■

■

Clean/replace the spark plugs

■

■

Replace the fuel filter

●

●

Replace air filter

2)

(paper filter)

■

■

Check the caster wheels (every 200 hours)

●

●

Replace the air cleaner’s pre-filter

2)

(foam)

■

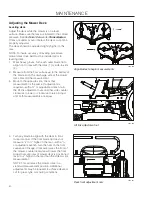

Check/adjust the mower deck

●

●

Check the engine valve clearance

3)

♦

♦

Perform the 300-hour service

3)

♦

♦

Summary of Contents for SPDZTR 42

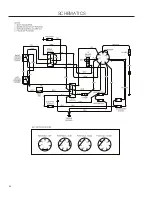

Page 48: ...48 schematics...

Page 61: ...SERVICE JOURNAL Action Date mtr reading stamp sign 61...

Page 62: ...SERVICE JOURNAL Action Date mtr reading stamp sign 62...

Page 63: ......

Page 64: ...P N 115 384127R2 10 06 10...