SPECIFICATIONS

The monocoque design chassis of the Model ZTR 1001 incorporates CMC laser

and CNC brake processes to form the twin 12 gauge side frames and 7 gauge

transmission and engine base plate.

The front body cover is made of rotational molded polyethylene. Front body

contains access panel for battery service.

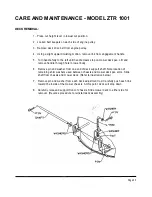

Cut height approximately 1" to 4" via 7 position lift handle.

Each deck is stamped steel construction:

36"-11 gauge 2 blades

36" cut width

Electric clutch.

Each rear wheel is independently driven by chain and sprockets th rough a friction

mechanical drive.

15HP Kohler Command, 4-Cycle, Single Cylinder, Overhead Valve, Air-Cooled,

Pressure Lubricated, With Oil Filter, Vertical Shaft, Aluminum Head and Block with

Cast Iron Cylinder Liner.

Electric by key switch operation with safety interlocks on parking brake and blade

drive.

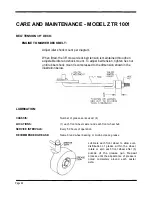

Front

9 X 350 X 4 ribbed tread.

Rear

1 6 X 6 . 5 0 X 8 Multi Trac Tread. .

Fuel:

2.7 gallons total

Engine:

2 quarts oil.

Width

Overall width with deflector retracted:

36" deck: 39" 42" deck: 46 1/2" 50" deck: 52 1/2"

Length 77" overall.

Weight 36" deck: 494 Ibs. 42" deck: 510 Ibs. 50" deck: 532 Ibs.

Additional information provided in service instructions underthe individual

component.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

Model ZTR 1001

CHASSIS:

BODY:

MOWER DECKS:

42"-13 gauge 3

blades

42" cut width

50"-10 gauge

3 blades

50" cut width

BLADE DRIVE:

TRANSMISSION:

ENGINE:

STARTING SYSTEM:

TIRES:

CAPACITIES:

DIMENSIONS:

NOTE:

Page8

Summary of Contents for ZTR 1001

Page 1: ...OPERATORS MANUAL...

Page 34: ...Page 31...

Page 35: ...Page 32...

Page 36: ...Page 33...

Page 37: ...Page 34...

Page 38: ...Page 35...

Page 39: ...Page 36...