14

CONTROLS

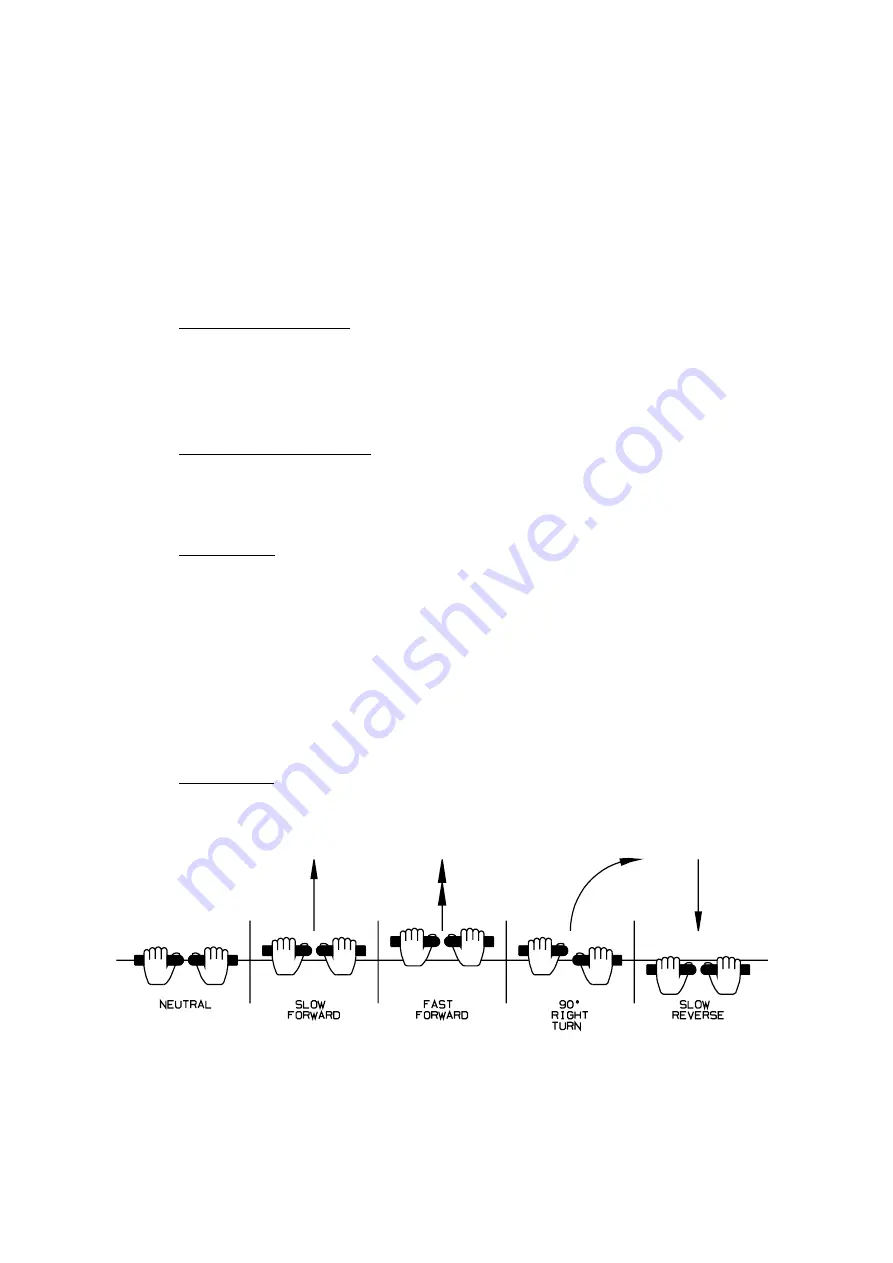

CONTROL LEVERS:

Note: For access to the seat, move control levers to neutral position and

swing them outward.

TO GO FORWARD:

•

From neutral position, gently push both control levers forward.

•

To increase speed, move levers further forward.

TO GO BACKWARD:

•

From neutral position, gently pull both control levers toward you.

TURNING:

•

Turning is controlled by moving one control lever slightly forward or

rearward of the other.

•

To turn left, move left lever rearward of the right lever.

•

To turn right, move right lever rearward of the left lever.

•

To turn on mowers own axis (zero turning radius), stop and move one

lever to reverse position and the other to forward position.

BRAKING:

•

To brake mower, move both levers in direction opposite of travel.

LEFT

TURN

OPPOSITE

Note: The pressure required to operate the mower is very light.

All manuals and user guides at all-guides.com