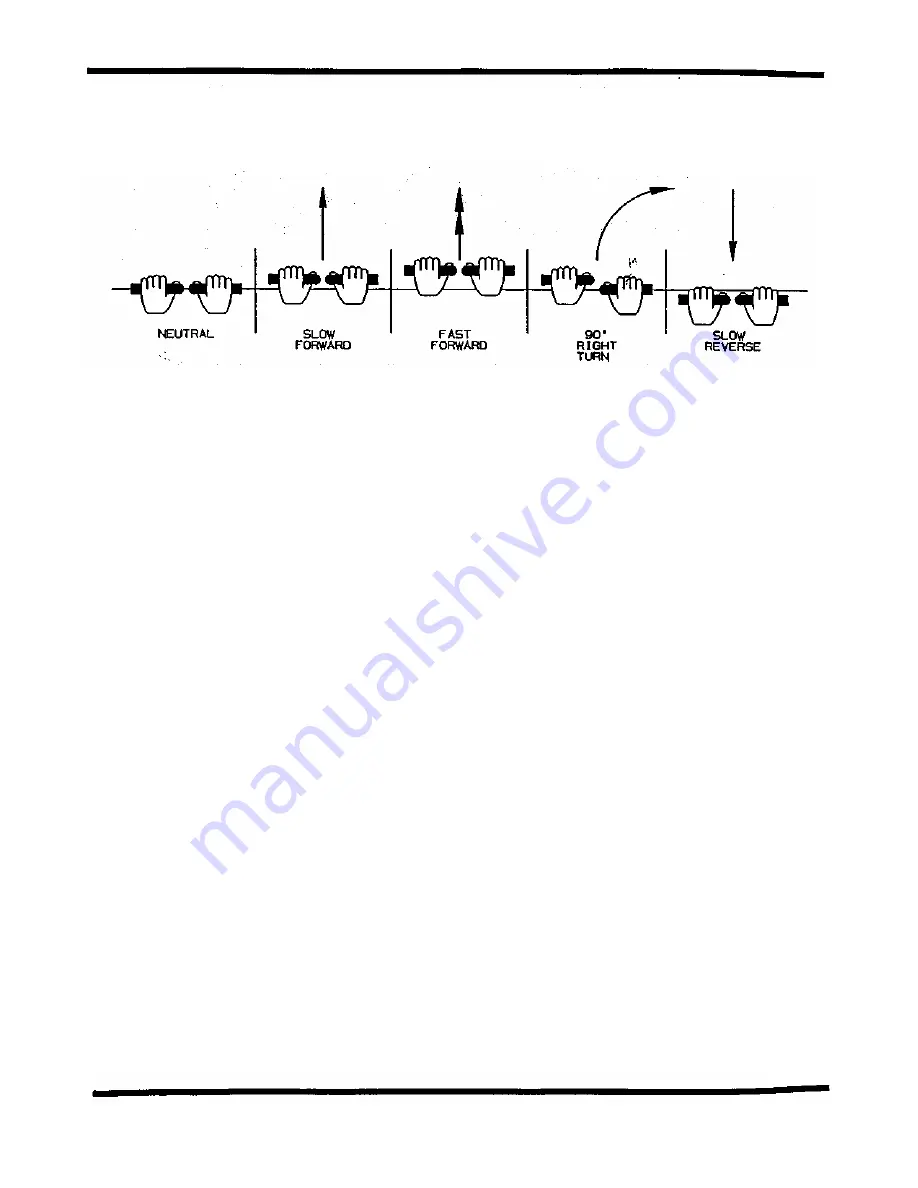

TO GO FORWARD:

From neutral position, gently push both drive levers forward. To

increase speed, move levers farther forward.

TO GO BACKWARD:

From neutral position, gently pull both drive levers toward you.

TURNING:

Turning is controlled by moving one drive lever slightly forward or rearward of the other.

To turn left, move left lever rearward of the right lever. »,

To turn "square corners" move lever of desired direction to neutral.

To turn on mower's own axis (zero turning radius) stop and move o ne lever to reverse

position and the other to forward position.

BRAKING:

To brake mower, move both levers in direction opposite of travel, release levers to

neutral, set parking brake. Park only on level surfaces.

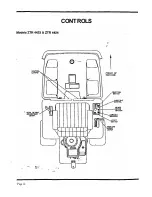

TWIN FUNCTION THROTTLE CONTROL LEVER:

Located on control panel to operators right.

Throttle control for engine speed.

Choking for engine starting.

T hrottle C9ntrol should be set to the MAXIMUM or wide open setting to insure adequate

cooling of the engine and to maintain mowe r deck blade speed while mowing.

CONTROLS:

Page 14