Page 23

CARE AND MAINTENANCE

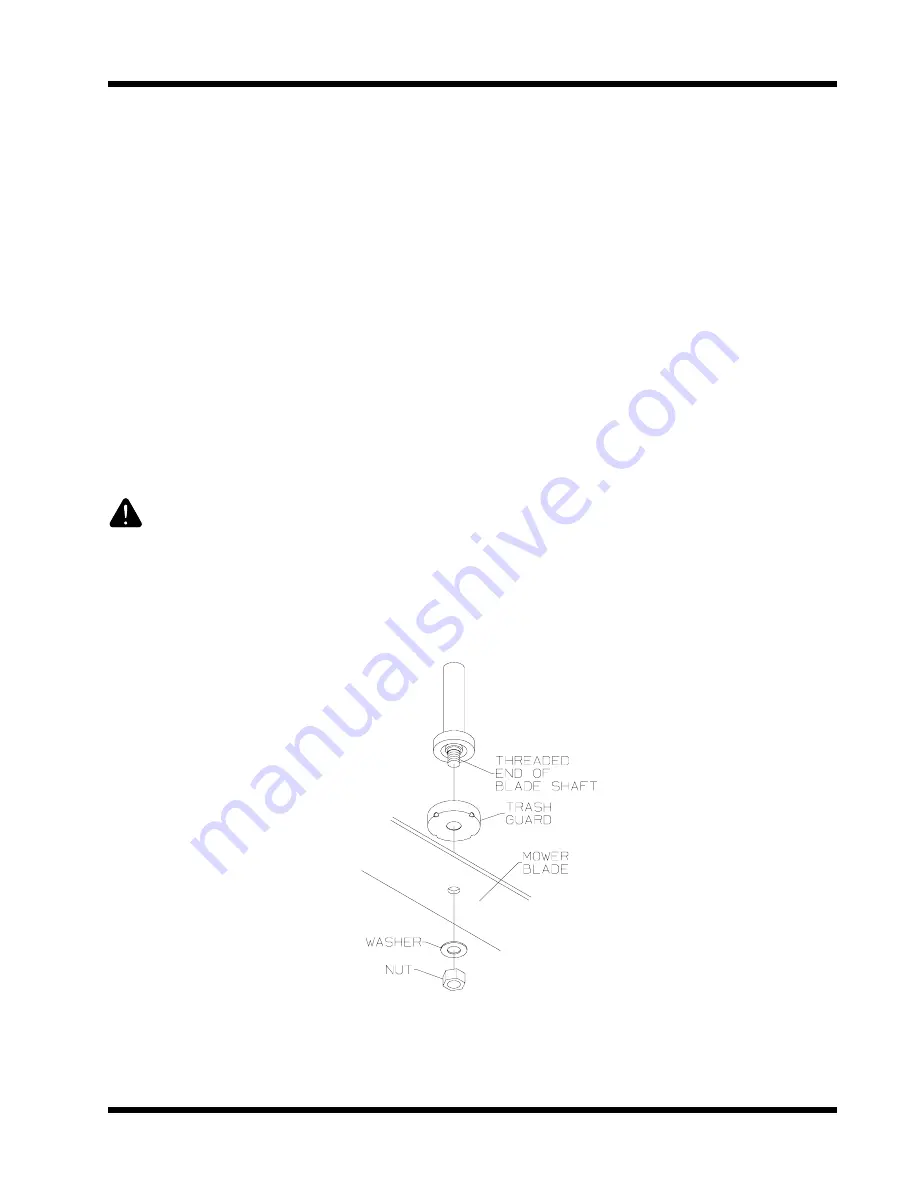

MOWER BLADE MAINTENANCE:

NOTE:

Observe proper blade position prior to removal.

1. Safely raise front of mower.

2. Hold or block blade from turning.

3. Loosen blade nut and remove bla

de.

4. When replacing blade, tighten blade nut securely. Refer to diagram.

CAUTION

Wear heavy, thick gloves when holding onto mower blade, avoid the sharp

edge of the blade.

NOTE: Be sure blade is centered on pilot before tightening nut to 60 ft. lbs. torque.

Summary of Contents for ZTR 4500 Series

Page 1: ...4500 SERIES ZTR MOWERS Operator s Manual 2001...

Page 36: ...Page 36 NOTES...

Page 37: ...Page 37 NOTES...

Page 38: ...Page 38 NOTES...