CARE AND MAINTENANCE

MODELS ZTR 5501 & ZTR 5601 DRIVE SYSTEM ADJUSTMENTS

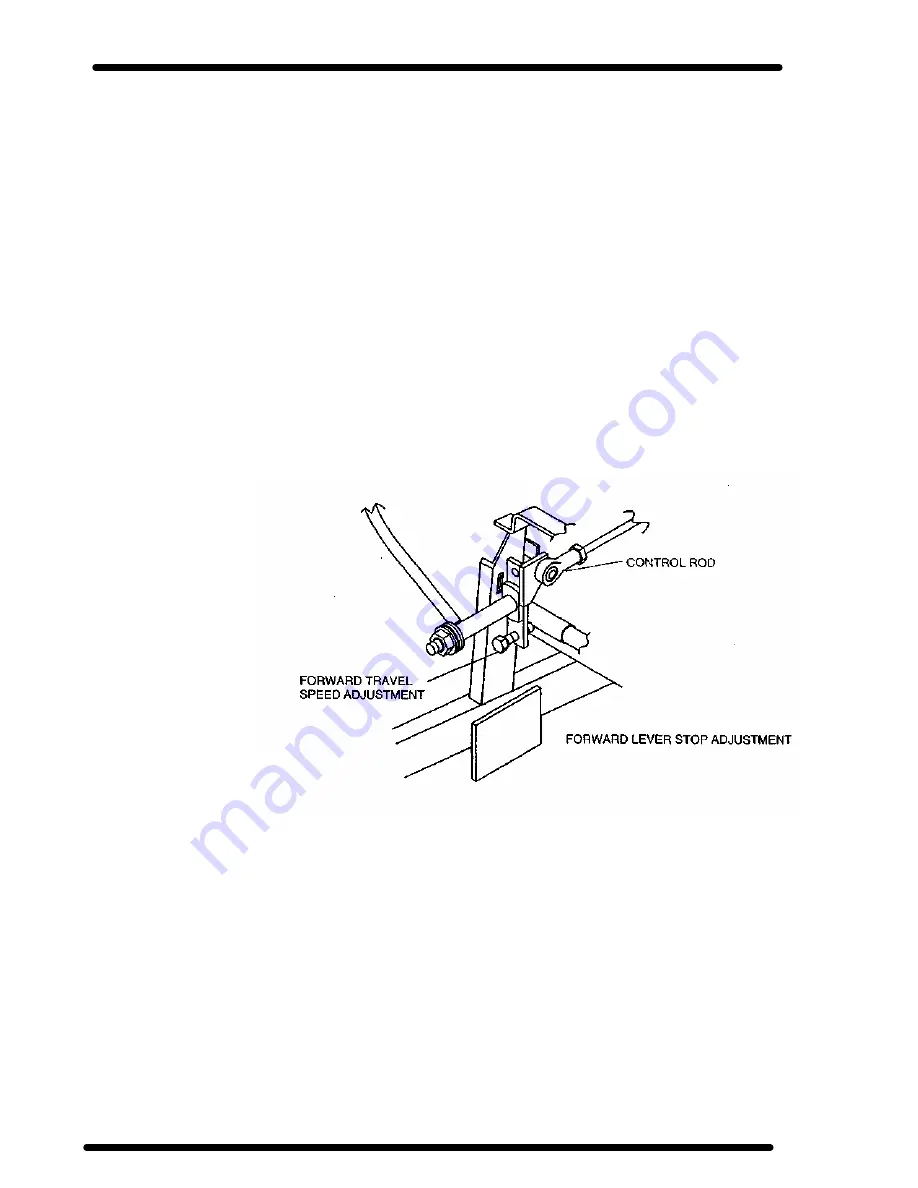

FORWARD TRAVEL SPEED ADJUSTMENTS:

Stop engine, move levers to drive position, lightly push each upper control lever forward

until a resistance is felt on the lever.

At this time, check that the forward lever stops on the bottom of each lever are hitting the

stop blocks.

If adjustment is required, loosen the lock nuts on the lever stop and turn the bolt in until the

lever hits the stop block before resistance is felt in the hydrostat.

NOTE:

Balance of travel speed. If mower tends to pull to either side, re -adjust lever

stop on fast side to slow the hydrostat down and even out the ground speed.

DO NOT SPEED UP THE SLOW SIDE, AS OVER STROKING OF THE

HYDROSTAT COULD RESULT IN DAMAGE TO THE UNIT.

If upper control levers are slightly offset following this adjustment, they can be

realigned by bending them slightly.

Summary of Contents for ZTR 5000 Series

Page 1: ......

Page 14: ...CONTROLS ...

Page 50: ...5421 Drive Pulley Hydro Gearbox ...

Page 51: ...5501 T Box Hydro Gearbox ...

Page 52: ...5601 T Box Hydro Gearbox ...

Page 53: ...5000 Series Gearbox ...

Page 54: ...5421 Mower Deck ...

Page 55: ...5501 Mower Deck ...

Page 56: ...5601 Mower Deck ...

Page 57: ...5421 Chassis ...

Page 58: ...5501 Chassis ...

Page 59: ...5601 Chassis ...

Page 60: ...5421 Fuel Hydro Tanks Fittings ...

Page 61: ...5501 Fuel Hydro Tanks Fittings ...

Page 62: ...5601 Fuel Hydro Tanks Fittings ...

Page 63: ...5421 Body ...

Page 64: ...5501 Body ...

Page 65: ...5601 Body ...

Page 66: ...5421 Wiring ...

Page 67: ...5501 Wiring ...

Page 68: ...5601 Wiring ...

Page 70: ......