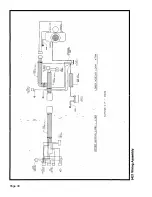

ZTR 5421 PARTS LIST

4584

Start Cable

5643

Input Gear - GB

4585

Battery Ground Cable

5644

Bearing - Gearbox

4587

Wire Cover 61 "

5645

Bearing Spacer - GB

4589

Covered Key

5648

CW Fan-Machined

4594

Wire Cover 14"

5649

CCW Fan-Machined

4598

Circuit Breaker

5650

Hydro

4645

Wire Cover 30"

5651

Hydro

4733

Seat Bottom

6065

Serpentine Idler Spring

4761

Seat Switch Assembly

6075

Engaging Idler Bracket Spacer

4783

Upper Wire Loom

6100

Outer Shaft Key

4784

Lower Wiring Loom

6101

Center shaft Key

4979

Hinge

6109

Serpentine Blade Drive Belt

5070

Key 3/16" SqX 7/8"

6111

Deck Drive Belt

5085

Brake Band

6168

Trash Guard

5170

Spring

6236

Mower Blade 42" Standard

5189

Bushing

6260

Blade Washer

5242

Plug w/Hole

6263

Hub Spacer - .459

5249

5/8" Bearing w/Snap

6264

Deck Hub - Machined

5257

Brake Drum (Keyed)

6272

V-Pulley

5283

Link

6282

Tapped Shaft Weldment Long

5522

Brake Link Right

6283

Tapped Shaft Weldment Short

5525

Brake Link Left

6293

Deflector Mount Bracket

5530

Control Pivot Shaft

6297

Deflector Pin

5531

Adjustable Collar

6366

Mower Deck Weldment

5537

Control Arm Bracket

6370

Mower Deck Assembly

5540

Neutral Adjust Collar

6392

Blow-By Baffle 42"

5554

Spacer 1/2" OD X 1/4"

6744

Spring

5558

Hose Fitting

7015

"L" Rod - 7"

5559

Hose Fitting

7594

Thrust Bearing

5560

Elbow - Male

7647

Wheel & Tire Assembly

5561

Adapter - Male (For 3/8" ID Hose)

7648

Caster Axle RH

5562

Adapter - Male (For 5/8" ID Hose)

7649

Caster Axle LH

5563

Tee - Cast Iron

8167

Caster Wheel Bearing

5564

Filter Head

8244

Clutch Kit

5565

Oil Filter

8384

Upper Body

5585

Tab

8386

Lower Body

5595

Hose 5/8" X 14"

8389

Frame Assembly

5602

Hose Guard Spring

8390

Front Rim - Black

5624

Tank Cap

8393

3/8" Black Hose 3.75

5625

Gearbox

8394

3/8" Black Hose 28.5

5632

3/8" Hose - 5"

8395

Wire Kit

5633

5/8" Hose - 2"

8429

Oil Valve/Hose Assembly

5635

Reservoir Assembly

8452

Battery Cover

5636

Brass Ferrule

8455

Serpentine Idler w/Stud

5641

G-Box Mount Spacer

8457

Deflector w/Decal

Page 34

Summary of Contents for ZTR 5421

Page 1: ......

Page 21: ...Page 18 ...

Page 22: ...FORWARD LEVER STOP ADJUSTMENT Page 19 ...

Page 28: ...Page 25 ...

Page 29: ...Page 26 ...

Page 30: ...Page 25 ...

Page 31: ...Page 26 ...

Page 32: ...Page 27 ...

Page 33: ...Page 28 ...

Page 34: ...Page 29 ...

Page 35: ...Page 30 ...

Page 36: ...Page 31 ...

Page 40: ...Page 36 NOTES ...

Page 41: ...NOTES Page 37 ...

Page 42: ...Page 38 NOTES ...