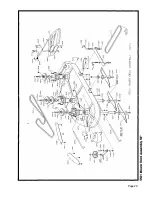

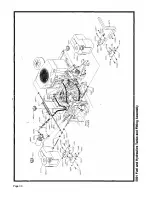

ZTR 5501 PARTS LIST

3318

3/8"-16X2 1/4" HH Bolt GR8

3655

Floor Pad Left Rear

3319

Idler Shock Mount

3656

Floor Pad Right Rear

3321

5/16"-18X8"HHBoltGR8

3669

Decal - Caution

3322

5/16"-18X51/2"HHBoltGR8

3695

J-Bolt

3325

3/8"-16X31/2" HH Bolt GR8

3702

Pulley

3326

3/8"-16X4" HHBoltGRS

3705

Velcro Strip - Hook

3331

M6 X P1 X 8MM HH Bolt GR8.8

3706

Velcro Strip - Latch

3334

Nylok Nut

3717

3/8" Hose Clamp

3337

Retaining Ring

3718

5/8" Hose Clamp

3338

M8 X 1 .25 P HWH Tap Screw

3721

Decal - Danger

3339

Snap Ring - 5/8"

3746

Decal - Parking Brake

3342

Washer .525 X 1 .375 X .25

3772

By-Pass Keeper

3343

Hub Bolt-Drilled

3773

LH Rod End

3344

Grease Zerk

3774

RH Rod End

3347

Washer 1 .033 X 1 .5 X .06

3805

Hand Grip (Black)

3349

#806 Woodruff Key

3812

Ignition Nut

3351

1/4"-20 X 1/2" HWH Tap Screw

3813

Protective Cap

3352

3/8"-16X1 1/4" HH Bolt GR5

3829

Fuel Line 33"

3356

#12-1 4X3/4" Tap Screw

3844

Decal - Hydro-Gear

3359

5/16"-18 X 3" HH Bolt GR5 Alt Head

3852

Spring

3360

5/16"-18 X 4" HH Bolt GR5 Alt Head

3857

Fuel Line 23"

3361

Stud 1/2"-13X2"

3861

Control Panel 50"

3362

5/16"-18X1" Tap Screw

3874

Seat Knob 5/1 6"- 18

3364

Washer - Bent

3876

Caster Spring

3368

1/4"-20 X 3/4" HWH Tap Screw

3878

Caster Plug

3369

1/4"-20 U Nut

3882

Hand Grip (Notched)

3370

1/4" Square Key X 2.50"

3887

Chrome Lug Nut

3373

6-32X1/2" HWH Slotted

3889

Drive Pulley 1.13 Bore

3374

6-32 Hex Nut x/Nylok ^> '

3890

Bearing

3375

L-Rod 3.5"

3896

Hub Cover

3391

1/8" X 1 1/2" Cotter Pin

3898

Clutch Spacer

3403

Bushing

3916

Decal - DIXON

3531

Decal - Operating Instructions

3917

Bar Sleeve

3536

Decal - Danger

3919

Hour Meter

3558

2 Gallon Tank w/Cap

3947

Fuel Cap

3578

Nylon Bushing

3948

Flip-Lok Bushing

3585

Decal - Cutting Height

3953

Nylon Bushing

3600

Rebound Mount

3963

Model Decal 5501

3601

Load Mount

3965

L-Rod 5.5

3602

Spacer Tube

4124

Solenoid w/Hardware

3603

ISO Mount Insert

4197

Ignition Switch

3635

Tee - Fuel Line

4198

Blade Drive Clutch Switch

3649

Fuel Line Clamp

4199

Light Switch

3653

Floor Pad Left Front

4217

Battery

3654

Floor Pad Right Front

4242

Deck Switch

Page 34

Summary of Contents for ZTR 5501

Page 1: ......

Page 22: ...ADJUSTMENT POINTS FOR T BOX BELT TENSION Page 19 ...

Page 23: ...FORWARD LEVER STOP ADJUSTMENT Page 20 ...

Page 29: ...Page 26 ...

Page 30: ...Page 27 ...

Page 31: ...Page 28 ...

Page 32: ...Page 29 ...

Page 33: ...Page 30 ...

Page 34: ...Page 31 ...

Page 35: ...Page 32 ...

Page 40: ...NOTES Page 37 ...

Page 41: ...NOTES Page 38 ...