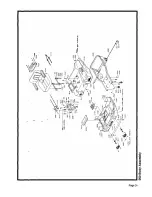

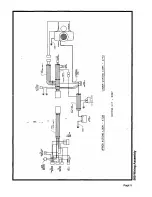

ZTR 560 PARTS LIST

3297

1/2"-13Thin Profile Nylok

3600

Rebound Mount

3298

Washer .51 5 X. 874 X. 031

3601

Load Mount

3300

Foam Pad

3602

Spacer Tube

3310

5/16"-18Thin Profile Nylok

3603

ISO Mount Insert

3318

3/8"-16X2 1/4"HHBoltGR8

3635

Tee - Fuel Line

3319

Idler Shock Mount

3644

Fuel Line 7 1/2"

3321

5/16"-18X8"HHBoltGR8

3646

Fuel Line 20"

3322

5/16"-18X51/2"HHBGR8

3649

Fuel Line Clamp

3325

3/8"-16X31/2"HHBGR8

3653

Floor Pad Left Front

3326

3/8"-16X4"HHBGR8

3654

Floor Pad Right Front

3331

M6XP1 X8MMHHBGR8.8

3655

Floor Pad Left Rear

3334

Nylok Nut

3656

Floor Pad Right Rear

3337

Retaining Ring

3669

Decal - Caution

3338

M8 X 1 .25 P HWH Tap Screw

3695

J-Bolt

3339

Snap Ring - 5/8"

3702

Pulley

3342

Washer .525 X 1 .375 X .25

3705

Velcro Strip - Hook

3343

Hub Bolt-Drilled

3706

Velcro Strip - Latch

3344

Grease Zerk

3717

3/8" Hose Clamp

3346

1/8" DiaX1 1/4" Cotter Pin

3718

5/8" Hose Clamp

3347

Washer 1. 033X1. 5 X. 06

3721

Decal Danger

3348

5/1 6"-1 8X3/4" Tap Screw

3746

Decal - Parking Brake

3349

#806 Woodruff Key

3772

By-Pass Keeper

3351

1/4"-20 X 1/2" HWH Tap Screw

3773

LH Rod End

3352

3/8"-16X1 1/4" HH Bolt GR5

3774

RH Rod End

3356

#12-1 4X3/4" Tap Screw

3805

Hand Grip - Black

3359

5/16"-18 X 3" HHB GR5 Alt Head

3812

Ignition Nut

3360

5/16"-18 X 4" HHB GR5 Alt Head

3813

Protective Cap

3361

Stud 1/2"-1 3X2"

3844

Decal - Hydro-Gear

3364

Washer - Bent

3852

Spring

3368

1/4"-20 X 3/4" HWH Tap Screw

3861

Control Panel 50"

3369

1/4"-20 U Nut

3876

Caster Spring

3370

1/4" Square Key X 2.50"

3878

Caster Plug

3373

6-32 X 1/2" HWH Slotted

3882

Hand Grip (Notched)

3374

6-32 Hex Nut w/Nylok

3887

Chrome Lug Nut

3375

L-Rod 3.5"

3889

Drive Pulley 1.13 Bore

3376

L-Rod 5"

3890

Bearing

3377

Serpentine Idler Spacer

3896

Hub Cover

3379

1/2"-13X3"HHBGR5

3898

Clutch Spacer

3380

7/16"-20X31/4"HHBGR5

3916

Decal - DIXON

3403

Bushing

3917

Bar Sleeve

3531

Decal - Operating Instructions

3919

Hour Meter

3536

Decal - Danger

3938

Deflector Spring

3558

2 Gallon Tank w/Cap

3947

Fuel Cap

3578

Nylon Bushing

3948

Flip-Lok Bushing

3585

Decal - Cutting Height

3952

Model Decal - 560

Page 34

Summary of Contents for ZTR 560

Page 1: ......

Page 22: ...ADJUSTMENT POINTS FOR T BOX BELT TENSION Page 18...

Page 23: ...FORWARD LEVER STOP ADJUSTMENT Page 20...

Page 29: ......

Page 30: ......

Page 31: ......

Page 32: ......

Page 33: ......

Page 34: ......

Page 35: ......

Page 40: ...NOTES Page 37...

Page 41: ...NOTES Page 38...