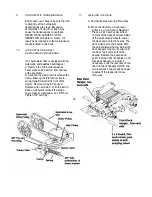

D. Check balance of blade by positioning

the blade on a nail or blade balance

pedestal. Grind the blade on the end that

is heavier until both sides balance.

E. Install blade, cup washer, lockwasher,

and bolt. Make sure to tighten bolt to 60

ft.lbs.

5.

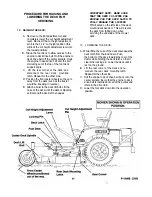

V-BELTS:

There are 3 V-belts on your

Dixon

Zero

Turning Radius Mower. They should be

checked every 50 hours. Replace any

belts found to be in poor condition. All

belts are equipped with spring loaded belt

tighteners and do not require tightening

adjustments.

6.

LUBRICATION:

A. Engine: Follow engine

manufacturer's recommendation.

B. Deck Spindles: Lubricate with 3

"shots" only, every 100 hours.

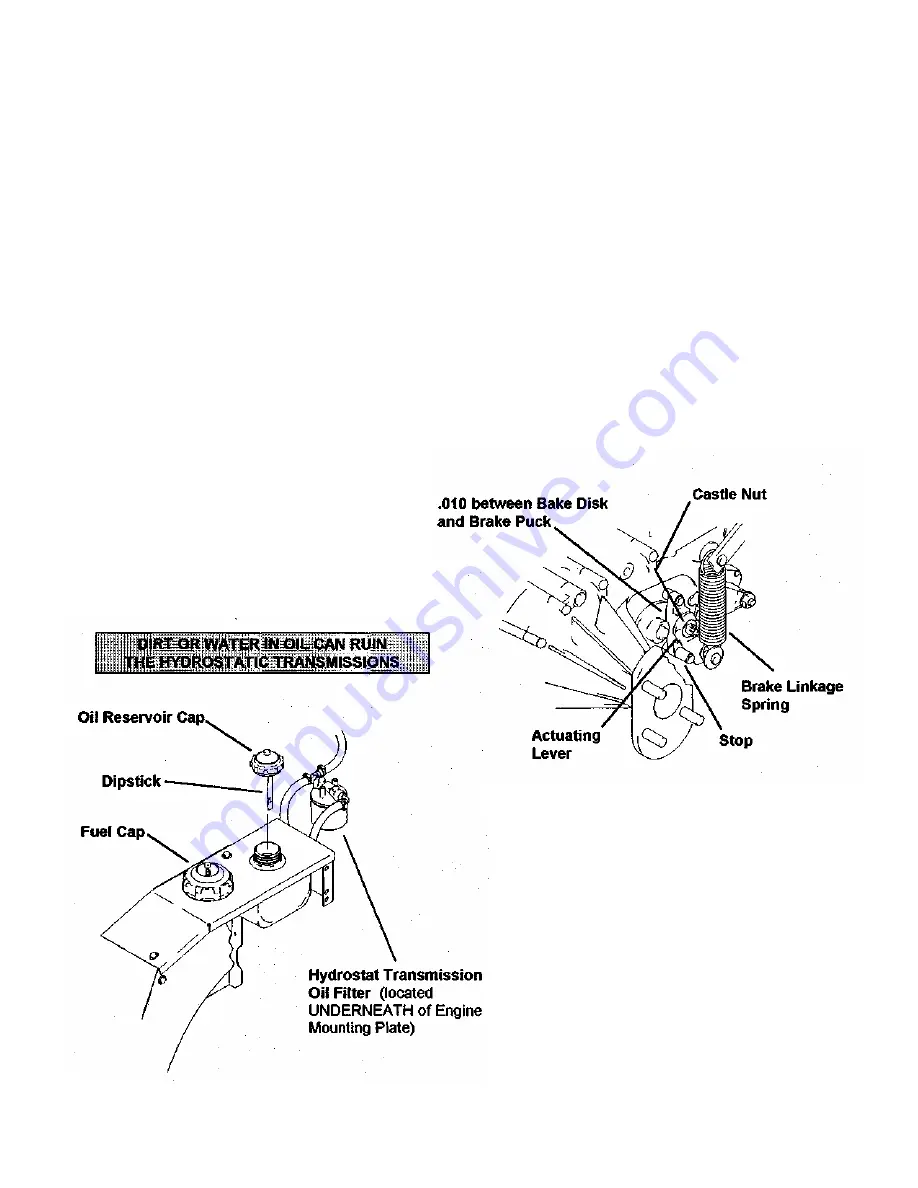

C. Hydrostatic Transmission & Filter:

Follow instructions listed below.

Check the oil level in hydrostatic

transmission oil reservoir after every 25

hours of usage. Clean the oil reservoir

cap and the area around it prior to

removal. Check the oil level on the

dipstick. The proper oil level should

register between the marked hole on the

dipstick and the end of the dipstick.

Replenish as needed with 20W-50 Motor

Oil.

DO NOT OVER FILL.

When

checking the oil level, be very careful to

keep the reservoir clean

Change the oil in the reservoir and

hydrostatic transmission filter after the

first 100 hours of use, then every 500

hours after that. Remove the filter and be

sure all oil has drained from the reservoir.

Replace with new filter (P/N 7252) and

20W-50 Motor Oil.

A. With the brake handle in the

"RELEASE" position and the actuating

lever against the stop, remove the cotter

pin from the castle nut. Insert a 0.010

feeler gauge between the brake disc and

the brake puck. Tighten the castle nut

with the feeler gauge inserted until the

gauge fits snugly«between the disc and

puck. The gap should not be so tight that

the feeler gauge cannot be reinserted

after removal. Back the castle nut to the

closest pin hole and reinsert the cotter pin.

7. PARKING BRAKE ADJUSTMENT:

P-11408

(2/99)

8

Summary of Contents for ZTR 700 Series

Page 1: ......

Page 4: ......

Page 16: ...12 P 11408 2 99...

Page 19: ...15 P 11408 2 99...

Page 20: ...NOTES...