9.

HYDROSTATIC TRANSMISSIONS:

Before each use, check to be sure that the

cooling fins of the hydrostatic

transmissions are clean. Excessive

accumulation of oil, dirt, or trash may

cause the transmissions to overheat.

NEVER WASH ACROSS TOP OF

RESERVOIR with water or steam. Fill

reservoir as required per the maintenance

schedule listed in this book.

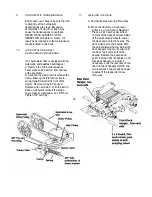

10. HYDROSTAT DRIVE BELT

REPLACEMENT PROCEDURE:

(The hydrostatic drive is equipped with an

automatic, anti-backlash belt take-up)

A. Remove the 3/8° bolt lockwasher,

heavy washer, and spring, from the rear

of the assembly.

B. Squeeze the clamp latch to release the

clamp, allowing the idler arm/pulley to

swing forward towards the front of the

mower. Remove old belt if required.

Replace with new belt. C. With the belt in

place on all pullies reinsert the spring,

heavy washer, lockwasher, and 3/8° bolt.

Tighten 3/8" bolt fully.

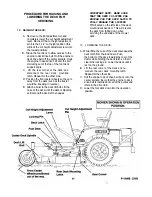

11. LEVELING THE DECK:

A. Set the tire pressure on all four tires

B. Move the tractor to a hard, level

surface (i.e. Concrete or blacktop).

Place a 2 x 4 board under all four

comers of the deck shell, just inside

of the anti-scalping wheels. Lower

the deck down onto the boards. The

deck must rest on the boards, NOT

the anti-scalping wheels.. Adjust the

deck hangers longer or shorter until

the deck "just" comes off of the

boards. Remove the boards and

verify that the deck is hanging on all

four deck hangers, re-adjust if

necessary. Lock the jam nuts on the

two front deck hangers. (NOTE: the

two rear deck hangers will be easier

to adjust if the fender skirts are

removed).

10

P-11408

(2/99)

Summary of Contents for ZTR 700 Series

Page 1: ......

Page 4: ......

Page 16: ...12 P 11408 2 99...

Page 19: ...15 P 11408 2 99...

Page 20: ...NOTES...