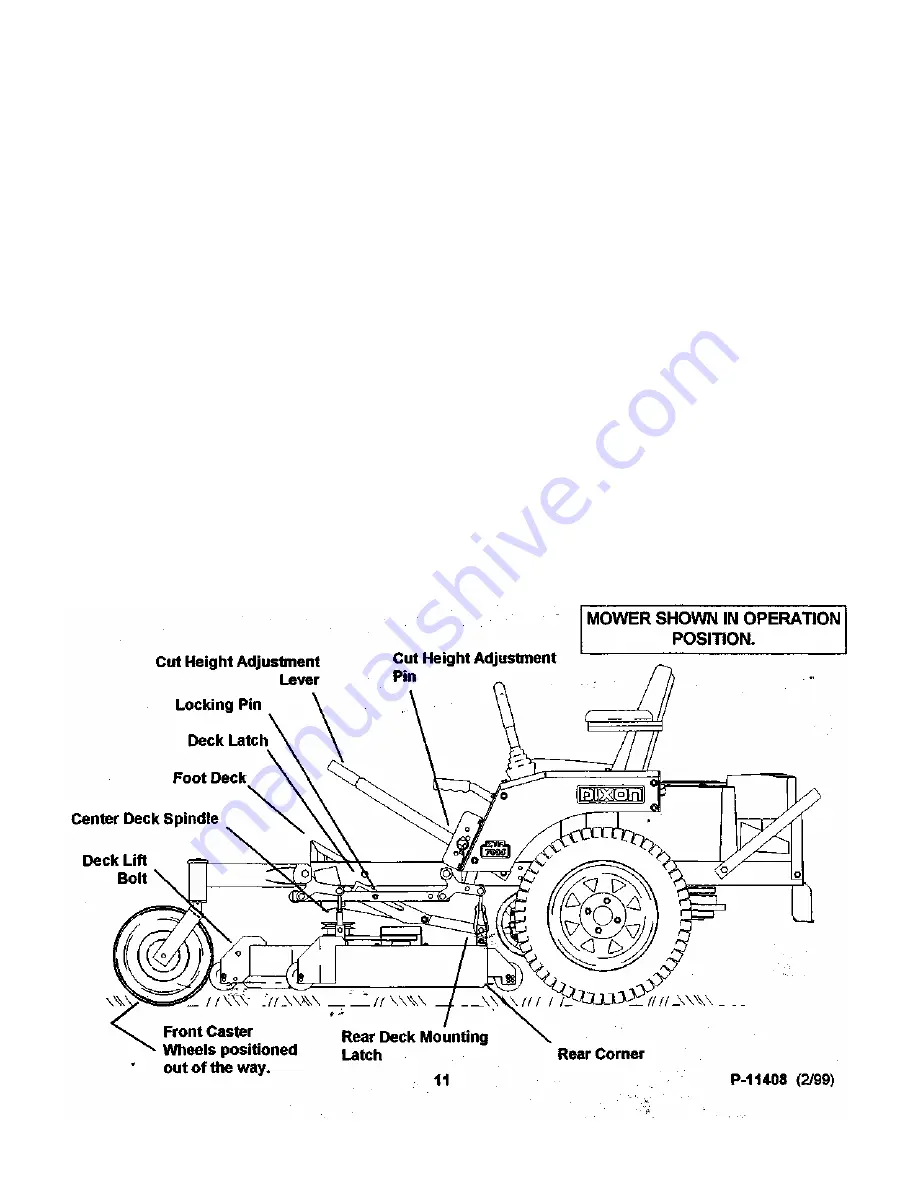

PROCEDURE FOR RAISING AND

LOWERING THE DECK FOR

SERVICING

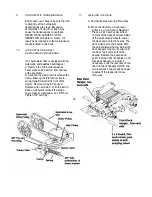

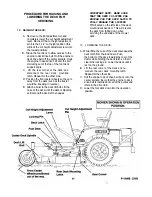

12. RAISING THE DECK:

A. Remove cut height adjustment pin and

completely lower the cut height adjustment

lever. Re-insert the cut height adjustment

pin into the 3-1/2° cut height position (this

will lock the cut height adjustment lever into

the lowest position).

. B. Flip up the foot deck to allow access to the

engine to deck drive belt. Roll the engine to

deck drive belt off the center spindle. Hook

the engine to deck drive belt onto the bolt

protruding out of the top of the foot deck

support angle.

C. Lift the rear corner of the deck and

disconnect the rear deck mounting

latch. Repeat for the other side.

D. Position the front caster wheels so they are

away from the deck (such as the tractor

would be traveling in reverse).

E. Attach a hoist to the deck lift bolt. Lift the

nose of the deck until the deck is standing

vertical and the deck latch engages.

IMPORTANT NOTE: MAKE SURE

THAT THE DECK IS LIFTED FAR

ENOUGH FOR THE DECK LATCH TO

FULLY ENGAGE THE LOCKING

PIN (located on the left side of the deck

mounting suspension). This will prevent

the deck from falling down when

servicing the underside of the mower

deck.

13. LOWERING THE DECK:

A. While lifting the nose of the deck disengage the

deck latch from the locking pin. Push

the bottom of the deck towards the rear of the

tractor while holding the deck latch so that it

clears the locking pin. Lower the deck until it

rest on the ground.

-B. Lift the rear comer of the deck and re -

connect the rear deck mounting latch.

Repeat for the other side.

C. Roll the engine to deck drive belt back onto the

center spindle. Insure that the engine to deck

drive belt is installed onto all of the pullies and

idlers in the drive train.

D. Lower the foot deck down into the operation

position.

Summary of Contents for ZTR 700 Series

Page 1: ......

Page 4: ......

Page 16: ...12 P 11408 2 99...

Page 19: ...15 P 11408 2 99...

Page 20: ...NOTES...