31

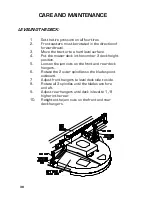

CARE AND MAINTENANCE

CHECKING & REPLENISHING OIL IN HYDROSTATIC

TRANSMISSION:

Dirt or water in oil can ruin the

hydrostatic transmissions.

Check the oil level in hydrostatic transmission oil

reservoir after every 25 hours of usage. Clean the

oil reservoir cap and the area around it prior to

removal. Check the oil level. Oil should be

approximately 1-3/8 below top of oil tank. Replenish

as needed with SAE 20W-50 motor oil. DO NOT

OVERFILL. When checking the oil level, be very

careful to keep the reservoir clean.

Change the oil in the reservoir and hydrostat

transmission oil filter after the first 100 hours of use.

Then every 500 hours after that. Remove the filter

and be sure all oil has drained from the reservoir.

Replace with new filter and SAE 20W-50 motor oil.

Please dispose of used oil at proper collection centers -

protect your environment

Summary of Contents for ZTR 8000G Series

Page 1: ...ZTR 2003 OPERATOR S MANUAL 8000G SERIES...

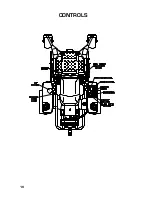

Page 18: ...18 CONTROLS...

Page 42: ...42 NOTES...