31

CARE AND MAINTENANCE

BELTS:

Check belts every 50 hours. Replace any belts found to

be in poor condition.

BELT TENSION:

Transaxle Drive Belt:

P/N 1684

No adjustment required.

Engine to Mower Deck Belt:

P/N 6111

No adjustment required. Correct belt tension is

maintained through a fixed engine location and a

spring loaded idler system. A pulsing movement of

the belt idler will be observed both during engagement

of the electric blade clutch and actual operation of the

mower deck.

Note: Engagement of the electric blade clutch switch

may produce a sharp high pitched chirp or

squeal as the belt tension loading is absorbed

by the idler system. This is normal and not a

sign of failure.

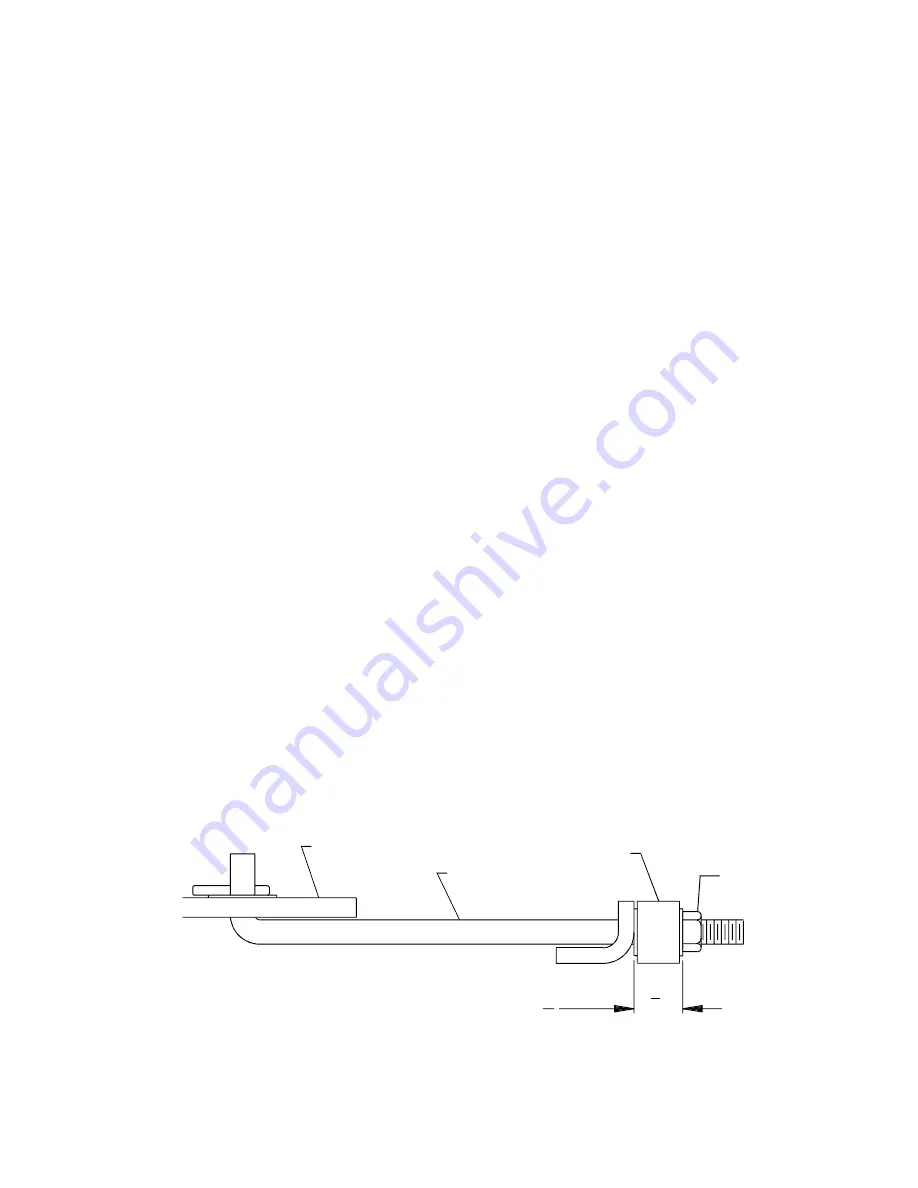

Mower Deck Serpentine Belt:

P/N 6109

Refer to illustration for adjustment procedure.

Idler Weldment

L Rod

Idler Shock Mount

Hex Nut

3

4

Tighten or

Loosen Hex

Nut to

achieve this

dimension

Summary of Contents for ZTR CLASSIC

Page 1: ...ZTR 2003 OPERATOR S MANUAL ZTR CLASSIC...

Page 42: ...42 NOTES...