CARE AND MAINTENANCE

34

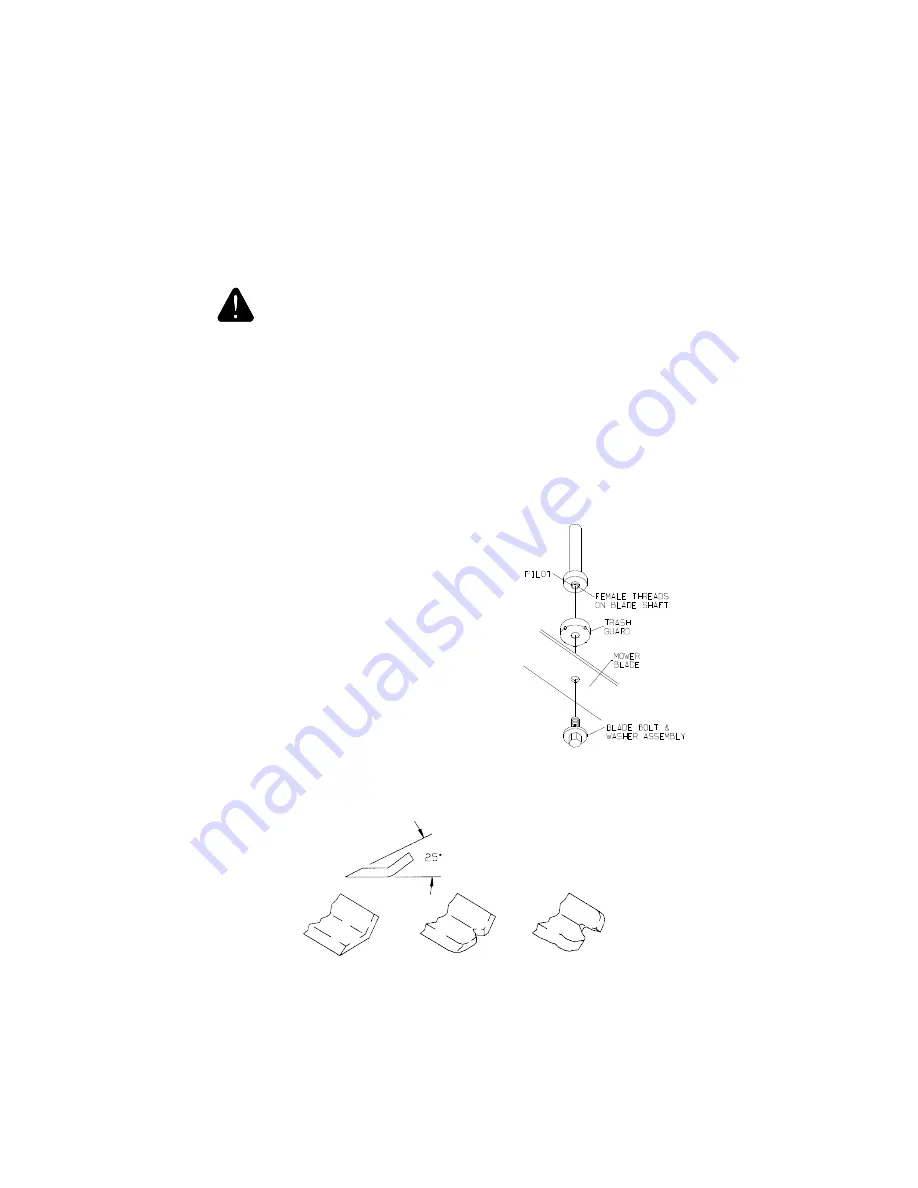

CUTTER BLADE MAINTENANCE:

CAUTION Stop engine and remove ignition key

for safety. Wear heavy, thick gloves

when holding onto cutter blade, avoid

the sharp edge of the blade.

Blades should be discarded when worn excessively.

DANGEROUS!

DO NOT USE

BLADE IN THIS

CONDITION!

When notch starts,

discard blade

New Blade

Check sharpness of mower blades after every 10

hours of operation. Observe proper blade position

prior to removal.

1. Safely raise front of mower.

2. Hold or block blade from

turning.

3. Loosen blade bolt and remove

blade.

4. When replacing blade, tighten

blade bolt securely. Refer to

diagram. Be sure blade is

centered on pilot before

tightening to 60 ft. lbs.