BATTERY

Fill with electrolyte solution to lower ring of battery. After _

initial filling, fluid level may be maintained with distilled

water.

Procedure for off-season storage:

1. Charge battery.

2. Disconnect cables from battery terminals. Identify

cables so that they may be easily reconnected to the

correct terminal. (Disconnect ground cable first and

.reconnect last.)

3. Clean top of battery and terminals.

4. Do not remove battery from mower.

5. To reactivate, reconnect cables to correct terminals

and charge battery if needed.

BELT ADJUSTMENT

The best tension for a V-belt drive is the lowest tension at

which the belts will not slip under normal load condition.

Check the tension on a new belt frequently during first

hours of operation and every 10-15 hours or monthly

thereafter. Too much tension shortens belt and bearing life.

Too little tension causes slippage and damages belt. Be

sure the belts and pulleys are kept free of foreign material.

If belt slippage occurs, tighten it just enough to prevent

slippage.

TRANSAXLE DRIVE BELT

No adjustment necessary; the spring-loaded Idler pulley

maintains proper belt tension throughout the belt life.

MOWER DRIVE BELT ADJUSTMENT See the Technical

Data Brochure for belt adjustment procedure on each

model.

REPLACE BELTS WHEN ADJUSTMENT CAN NO

LONGER BE MADE SATISFACTORILY OR IF BELTS

BECOME WORN.

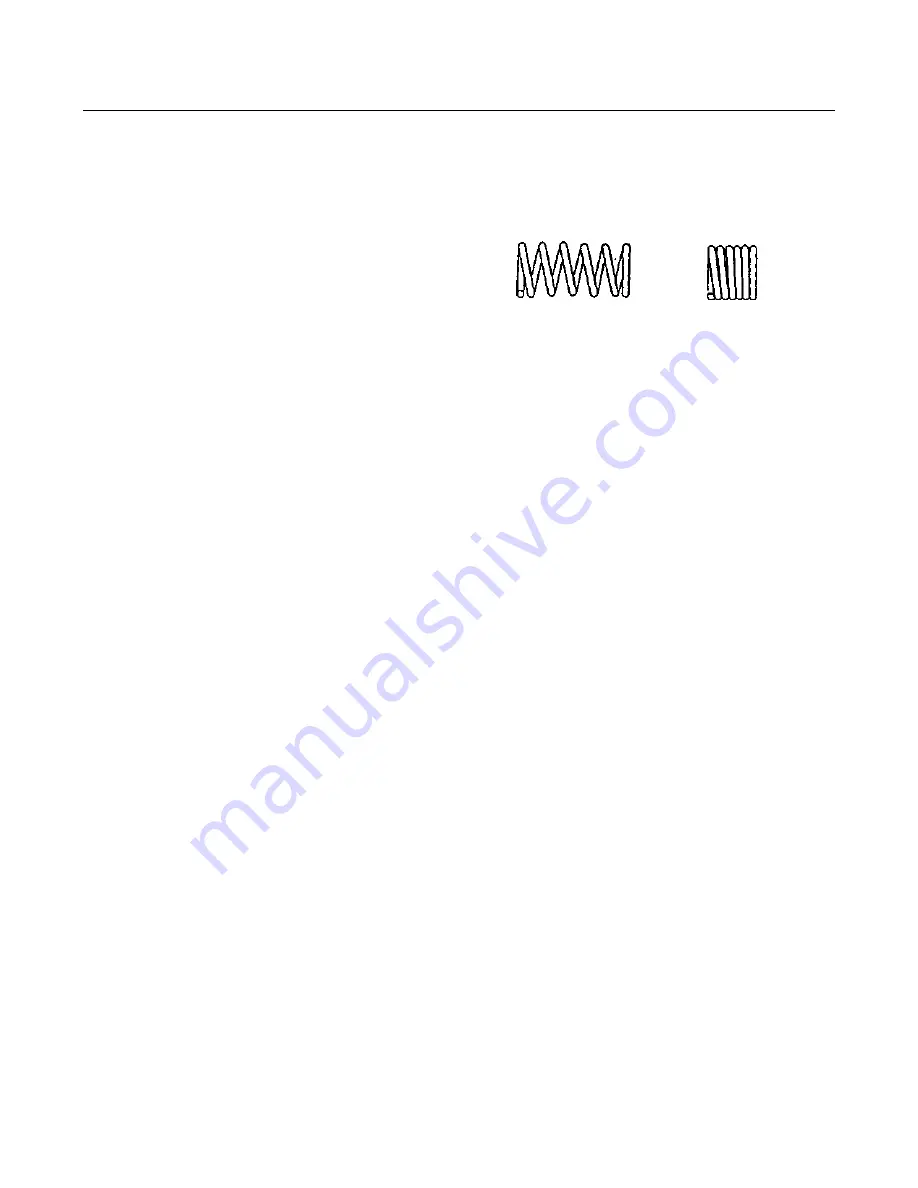

DRIVE CHAIN ADJUSTMENT This mower Is equipped with

manually adjusted drive chain tension Idlers. One for each

chain at the rear of the mower. To adjust drive chains, simply

tighten nut on rod P/N1683, until spring P/N 5133 Is

compressed as shown in the drawing. Inspection of the

chains will show the need for adjustment when the spring

P/N 5133 is free of tension. Inspect chains after each 10-12

hours of operation.

NEEDS ADJUSTMENT

PROPER TENSION

Proper lubrication is important for effective roller chain

operation. Use high quality lubricating oil or motorcycle

chain lube. (Do not use grease or extra heavy oil.) Apply

drops of oil to the chain joints every 10-15 hours of

operation. DO NOT LUBRICATE IF OPERATED IN HEAVY

DUST OR SAND. .

FRONT CASTER ASSEMBLY Each caster assembly has a

grease fitting located on the under side of the bearing. For

best results, use any good multipurpose grease every 10-15

hours of operation. All other bearings on your mower are

sealed and require no lubrication.

WHEELS AND TIRES

Correct tire pressure is essential to the correct operation of

the mower. The correct pressure for the rear drive tires is 8-

10 Ibs. for size 18 X9.50-8 and 12-14 Ibs. for size 16 x 6.50-8

tires. The front tires should be inflated to 20-24 Ibs. Lug

nuts should be checked periodically to assure they are

tight.

Summary of Contents for ZTR Zero Turn Riding Mower

Page 1: ......