15

?

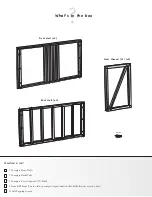

What’s in the box

1 Long Catch Track

2 Short Catch Tracks

2 Countertop Studs

2 Precut Appliance Tracks

Self-Tapping Screws (Amount needed for Assembly: up to 26)

Check List

Countertop Studs

Long Catch Track

Short Catch Tracks

Precut Appliance Tracks

Screws

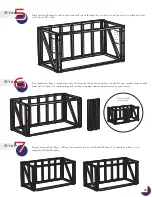

2 Precut Appliance Tracks

8 Self-Tapping Screws

Check List

Screws

Precut Appliance Tracks

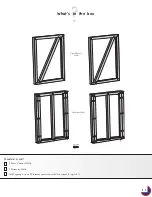

Slide-In and Drop Cutout (Pages 17 - 25)

Double Door Cutout (Pages 26 - 28)

Summary of Contents for Angela 'L' Island

Page 1: ...Angela L Island Module assembly Instruction Manual Easy to Follow ...

Page 5: ...68 inch Quick Panel Assembly x2 ...

Page 10: ...90 Corner Quick Panel Assembly ...

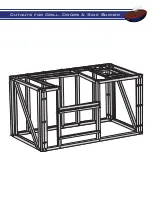

Page 14: ...Cutouts for Grill Doors Side Burner ...

Page 28: ...28 You should now have a complete Cutout for your Double Doors 5 5 Step ...

Page 33: ...Cutouts for Refrigerator Sink ...

Page 43: ...Full Angela L Island Assembly ...