2

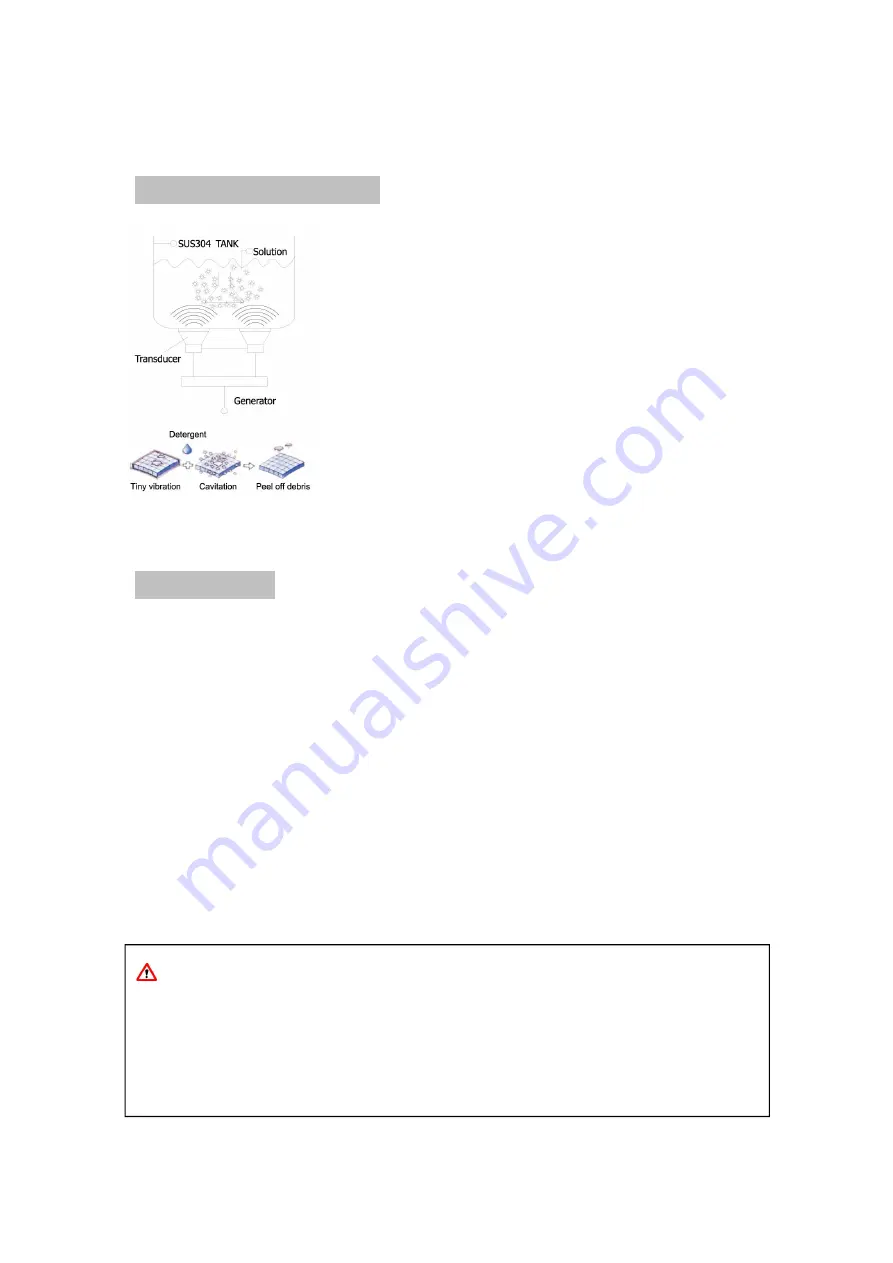

ULTRASONIC PRINCIPLE

PREPARATION:

1.

Carefully unpack the cleaner, remove all packing materials and check whether any

parts have become loose or damaged during transit.

Contents:

a: Main machine

b: Sound proof lid

c: Power lead

d: Outlet filter

e: Mesh basket (Optional)

f: Manual

2. Place the cleaner on a flat, clean surface and ensure that the cooling fan will get

adequate ventilation, and that all controls are set to off, and the drain tap is

closed.

3.

Ensure that the power lead is securely plugged into the cleaner, and that no part of

the lead is likely to contact with moisture.

4. Carefully fill at least 7cm depth of the tank with a solvent solution. Based on

cleaning requirements, we recommend to use a small amount of cleaning solution

because this will help increase the cleaning performance. Now the cleaner is ready

for use.

Ultrasonic cleaning is based on the cavitation effect caused by

high frequency ultrasonic wave vibration signal in the fluid.

Microscopic bubbles are formed, and then implode violently

causing the cavitation which create an intense scrubbing action

on the surface of the item being cleaned. The bubbles are small

enough to penetrate microscopic crevices, cleaning them

thoroughly and consistently.

Ultrasonic cleaning is extremely effective at removing dirt and

grime which would normally require tedious manual cleaning by

hand. It has been used to clean a wide variety of instruments and

mechanical parts such as carburetors, returning them to almost

“like new” condition without damage to delicate parts.

Attention

While the machine is working normally, the syntony of the ultrasonic wave and tank gives

a well-proportioned sound with no shudder on the surface of the water but sprays

generated by the tiny bubbles. If there are discontinuous surges, please add or reduce a

little of washing solution in the tank to stop the surges, which is good for get a better

cleaning effect.