20 | AC10G(H) man.

MAINTENANCE PROCEDURE SCHEDULE

WARNING! Qualified service personnel should perform any service procedure not covered

in the maintenance schedule below.

WARNING! The air compressor should be turned off and unplugged from the power

source before any maintenance is performed, air should also be bled from the tank and the

unit should be allowed to cool. Personal injuries could occur from moving parts, electrical

sources, compressed air or hot surfaces.

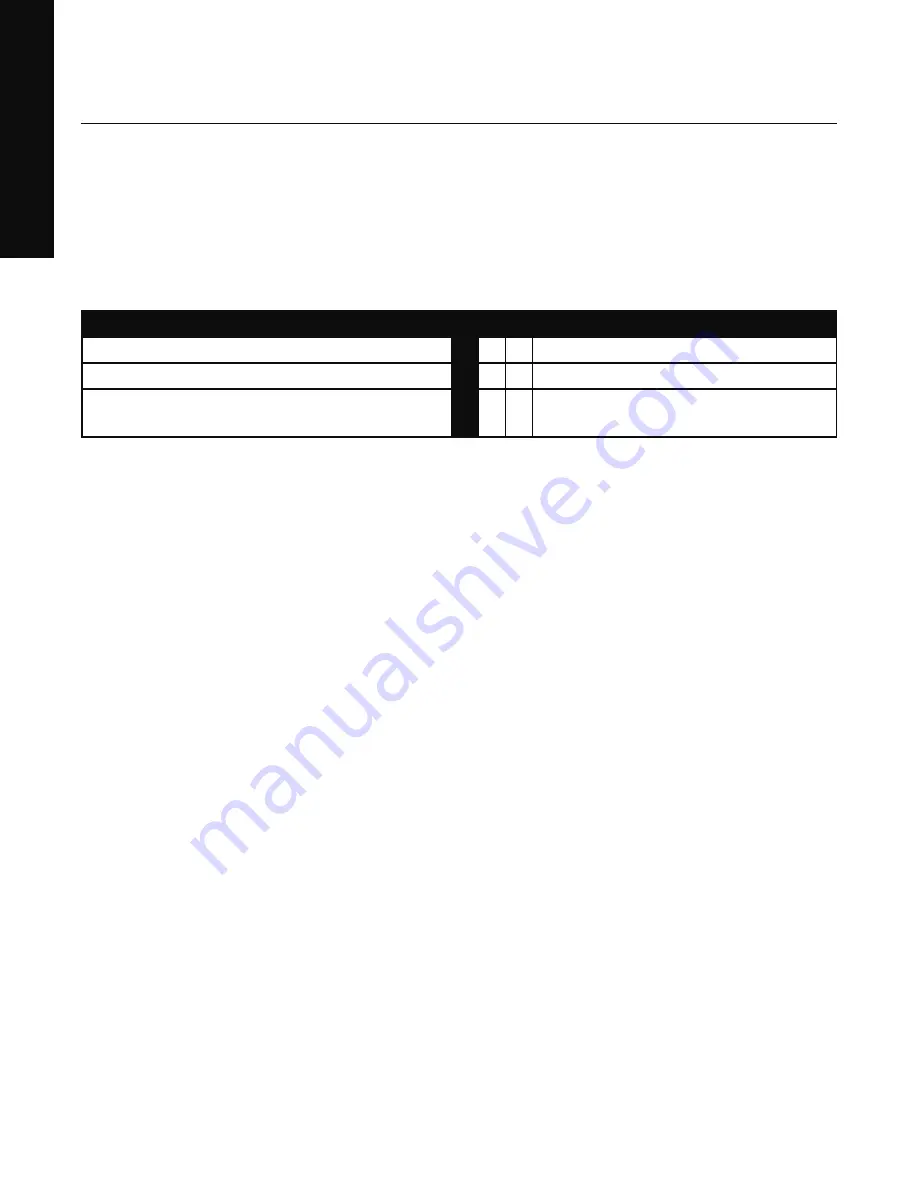

PROCEDURE

1 2 3

LEGEND

Check tank safety valve

BEFORE EACH USE OR DAILY 1

Overall unit visual check

AFTER FIRST 10 HOURS 2

Check air filter (more frequently in dusty or humid

environments)

EVERY 100 HOURS 3

WARNING! To ensure efficient operation and longer life of the air compressor unit, a

routine maintenance schedule should be followed. The following schedule is geared

toward a consumer whose compressor is used in a normal working environment on a daily

basis. If necessary, the schedule should be modified to suit the condition under which

your compressor is used. The modifications will depend upon the hours of operation

and the working environment. Air compressors used in an extremely dirty and/or hostile

environment will require a greater frequency of all maintenance checks.

ENGLISH

Summary of Contents for AC10G

Page 5: ...SECTION I SAFETY ...

Page 11: ...SECTION II INSTALLATION ...

Page 14: ...SECTION III OPERATION ...

Page 18: ...SECTION IV MAINTENANCE ...

Page 22: ...SECTION V PARTS SCHEMATICS ...

Page 25: ...v 220629 25 SCHEMATICS ENGLISH ...

Page 30: ...SECTION I SÉCURITÉ ...

Page 37: ...SECTION II INSTALLATION ...

Page 40: ...SECTION III FONCTIONNEMENT ...

Page 44: ...SECTION IV ENTRETIEN ...

Page 48: ...SECTION V PIÈCES ET SCHÉMAS ...

Page 51: ...v 220629 51 SCHÉMAS FRANÇAIS ...

Page 52: ......