MAINTENANCE Tl PS :

1 . G rease : Magnal ube®-G.

Magnal ube®- G is a m ultipu rpose extreme pressure lu brica nt containing

Teflone, ma nufactu red by: Sa unders Ente rprises, I nc.

1 1 -5 1 44th Road

Long I sla nd City, NY 1 1 1 0 1

PH: (7 1 El) 729 - 1 ODD FX: (7 1 8) 729-2590

2. Hyd ra ul ic oil : Drydene Pa rad ene .

Tool su pplied with Dryde n e Paradene

AW32

hydra ulic oil.

see COLD WEATHER NOTE, page 2 .

Ma nufactu red by: Dryden Oil Com p a ny

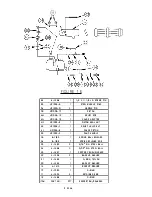

0- RI NG IN STALLATION :

9300 Pulaski Highway

Baltim o re, MD 2 1 220

P H: (41 0) 574-5000 FX: (4 1 D) 682-9 408

1 . C le a n e a c h ring groove, th en apply a l ig ht coating of hyd rau lic oil or g rea se

to the g roove or packing cham ber.

2.

Completely seat ring in g roove o r packing cham ber.

3. Apply a lig ht coat of hydra u lic oil or g rease to the ram lip seal a n d al l

0 -ri n g s u rfaces.

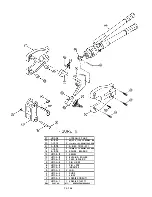

RESEATI NG

or

BALL VALVE S EATS (SEE FIGU RE 20):

The reseating of the ba ll va lve seats m ust be accomp lished each time a ba l l

valve i s repl aced.

BALL 25 (9/32" IJ IA.)

1 . Before performing a ny valve work, securely position pu m p body 37 in a soft

jaw equipped vise. Pl ace a new ba ll 25 (9/32" dia . ) on the va lve seot.

Position a 1 /4" dia . pin pu nch over the bal l and strike th e punch with a sha rp

blow,

2.

R EMOVE AND DISCARD THIS DAMAGED BALL! DO NOT USE!

3. U se a new ba ll 25 (9/32" dia . ) w h en reasse m bl i ng the tool.

BALL 26 (3/ 1 6" IJ IA.)

1 . Before performing a ny valve work, securely position pu m p body 37 in a soft

jaw equipped vise. Pl ace a new ba ll 26 (3/1 6" dia . ) on the va lve seat.

Position a 3/ 1 6 " dia . pin pu nch over the bal l and strike the punch with a

sharp bl ow.

2. R EMOVE AND

DISCARD

THIS DAMAGED BALLI

DO

NOT USE!

3. U se a new ba ll 26 (3/1 6" dia . ) w h en reasse m bl i ng the tool.

2 1 OF 28

Summary of Contents for HC134

Page 26: ...PORT ON SEE NOTE p SIDE E 1 6...