4

Assembly

Hi-Cap 40 Grain Cleaner

Step 27 Install the belt shield by putting a ½” nut on each shield mounting bolt, then place

a ½” flat washer to each bolt and continue by putting the shield into position. Se-

cure with another ½” flat washer, followed by a ½” nut. Adjust the shield so that it

will properly protect both pulleys. See Photo 43.

Step 28 The cone screens are usually installed at the factory. Should replacement or

change be necessary, remove the straps and self-tapping screws. A variety of

cone screens are available for the individual needs. See Page ???.

Outside screens are installed by wrapping the screen around the outside of the

drum. BE SURE outside screen is lapped as shown in Photo 46. If incorrectly

installed, grain will get behind the screens, causing them to work their way off the

drum. Place head of machine screws in direction of drum rotation.

For easy placement of outside drum screens, two door springs can be attached to

either a small piece of steel or wood with hooks to hook into the screen. Then, by

using a stick or broom handle, tap the screen lightly. The door springs will take all

the excess slack out of the outside screen so the drum straps can be easily put on

and secured. Straps should be secured with ¼” and 2-

1

/

2

” machine screws and

nuts. See Photos 47 and 48.

NOTE

Screen lap and outside drum straps should NOT be spliced on the same tumbling

bar.

Outside drum straps that are placed directly over drum rings should be tightened

securely. Common sense should be used when tightening straps that only come

in contact with the outside drum tumbling bars. Deforming of the bars could result

if these straps are over-tightened. BE SURE straps are positioned as shown in

Photos 47 and 48. REMEMBER, screen lap and outside drum straps should NOT

be on the same tumbling bar.

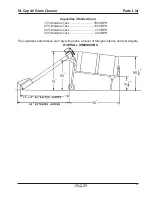

Step 29 By loosening the setscrews and turning the turnbuckle, you can adjust the slant of

your drum for proper operation. See Photo 49. The grain will pass through the

screener faster with a steep slant. The cleaning action will be more thorough with

less slant.

IF TRASH PAN EQUIPPED:

Step 30 The drum side panel will mount with the channel edge on the top and to the out-

side. Bolt the end shield to the front end of the side panel using two ¼” x ½” pan

head machine screws, hex flange lock nuts.

Step 31 Bolt the two posts to the drum side panel using ¼” x ¾” hex bolts, lock washers

and hex nuts.

Assembly Instructions

(continued)

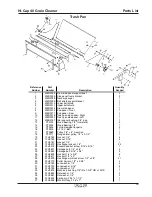

Summary of Contents for HI-CAP 40

Page 1: ...OWNER S MANUAL HI CAP 40 GRAIN CLEANER PNEG 1146 Date 9 21 06 PNEG 1146...

Page 2: ......

Page 15: ...9 Parts List Hi Cap 40 Grain Cleaner MODEL 40 HI CAP GRAIN CLEANER PARTS...

Page 17: ...11 Parts List Hi Cap 40 Grain Cleaner 8 x 8 Auger...

Page 19: ...13 Parts List Hi Cap 40 Grain Cleaner 4 x 15 Fines Auger...

Page 20: ...14 Parts List Hi Cap 40 Grain Cleaner...

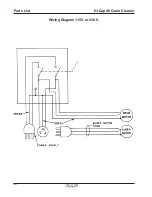

Page 22: ...16 Parts List Hi Cap 40 Grain Cleaner Wiring Diagram 115V or 230 V...